A 6 ton steam boiler is one of the most widely used industrial boiler capacities across global manufacturing sectors. With a rated output of 6,000 kg of steam per hour, this boiler size provides a perfect balance between steam demand, fuel efficiency, and operational cost. Whether it is used in food production, textile processing, chemical manufacturing, or construction, the 6-ton steam boiler plays a crucial role in providing stable heat and consistent steam supply.

This guide explains how 6-ton steam boilers work, their core applications, available fuel types, efficiency factors, and how to choose the right model for your industrial needs.

1. What Is a 6 Ton Industrial Steam Boiler?

A 6-ton steam boiler is an industrial pressure vessel designed to generate steam at a rate of 6 tons per hour. In most cases, these boilers operate under medium pressure, ranging from 1.0 MPa to 1.6 MPa, depending on production requirements.

Why 6 tons?

- Matches the steam consumption of medium-scale factories

- More fuel-efficient than 4-ton models

- Lower investment compared to 10-ton or larger boilers

Common Technical Characteristics

- Horizontal fire-tube or water-tube design

- Fully automatic control system

- High thermal efficiency (85%–98%)

- Customizable fuel systems: gas, oil, biomass, coal

This makes the 6-ton boiler extremely versatile across industries.

2. Key Technical Specifications

2.1 Steam Capacity

- 6,000 kg/h continuous output

- Ideal for high-load production environments

2.2 Operating Pressure Options

- Low pressure: 0.7 MPa

- Medium pressure: 1.0–1.6 MPa

- High-pressure options available

2.3 Thermal Efficiency

- Standard models: 85%–92%

- High-efficiency/condensing models: 95%–98%

2.4 Structural Design

- Fire-tube boilers for general industries

- Water-tube boilers for chemical or continuous operations

2.5 Safety & Automation

- PLC intelligent control

- Flame monitoring

- Automatic water feeding

- Over-temperature & over-pressure protection

- Real-time display and remote control

3. Industrial Applications of 6-Ton Steam Boilers

Because of their excellent heating capacity and stable output, 6-ton steam boilers are widely used across industries.

- Cooking

- Sterilization

- Pasteurization

- Baking & drying

- CIP cleaning systems

- Dyeing

- Printing

- Finishing

- Drying

- Heating reactors

- Distillation

- Solvent extraction

- Pressure control

3.4 Paper and Packaging Industry

- Paper drying

- Corrugated box production

3.5 Pharmaceutical & Biotechnology

- Clean steam

- Sterilization

- Fermentation heating

3.6 Construction Materials

- Concrete curing

- AAC block production

3.7 Agriculture & Farming

- Animal feed production

- Greenhouse heating

- Equipment sterilization

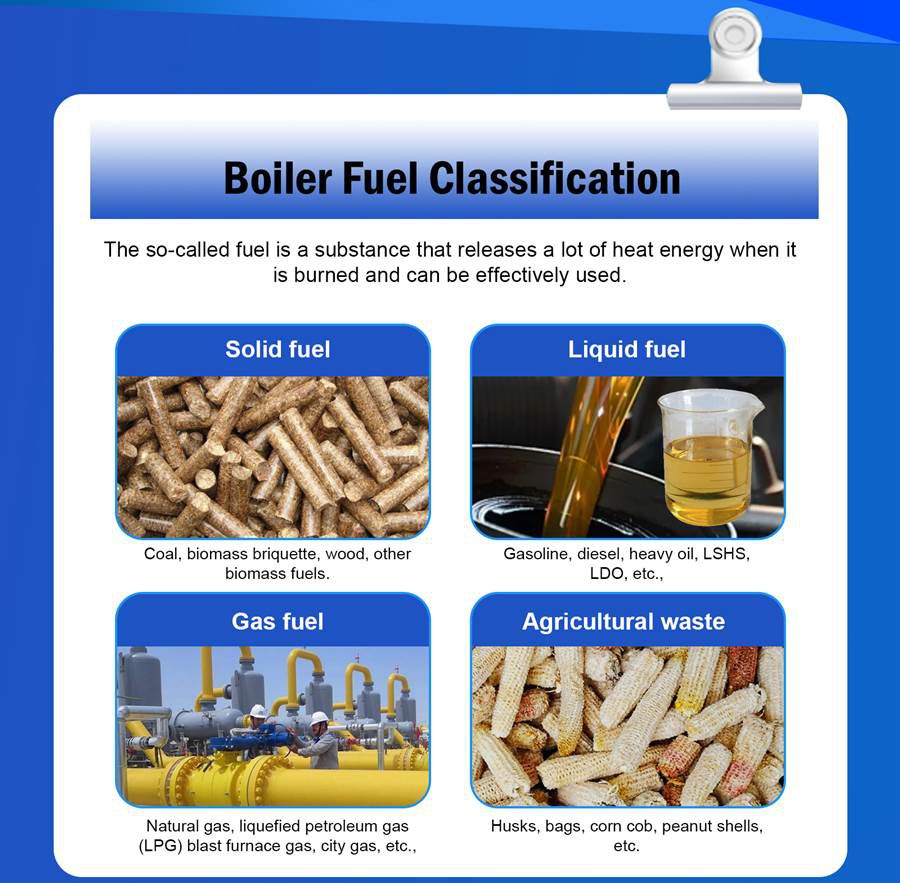

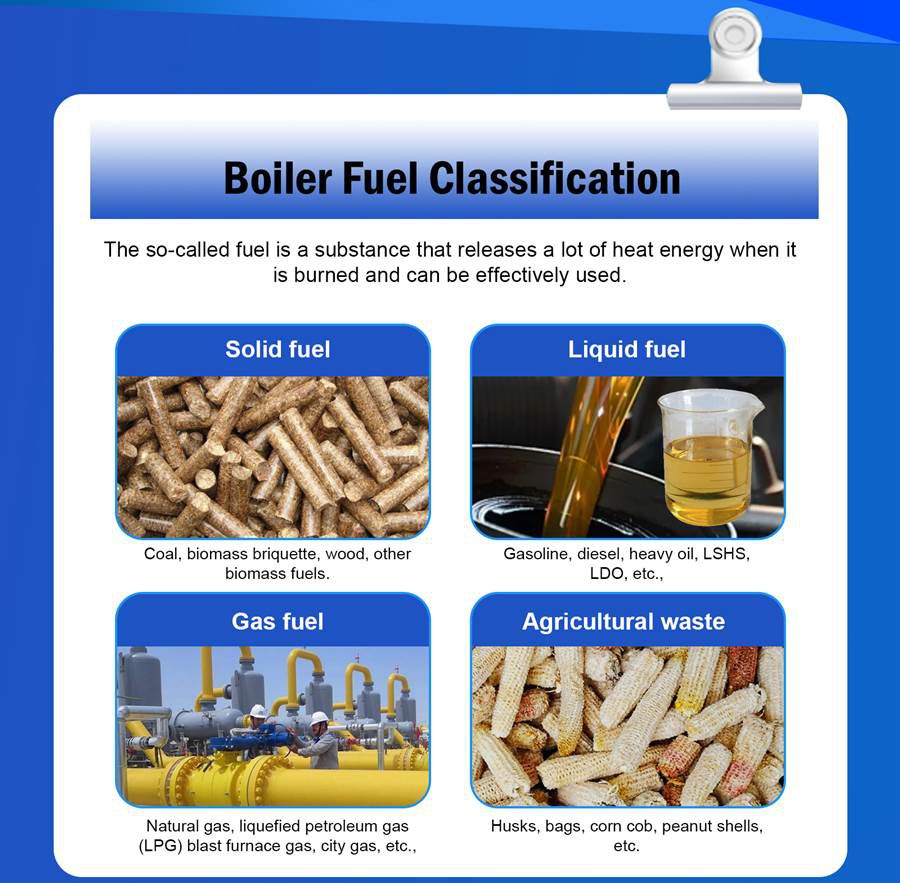

4. Fuel Options for 6 Ton Steam Boilers

Fuel: Natural gas, LPG, LNG

- High efficiency (up to 98%)

- Lowest emissions

- Clean & easy maintenance

Limitations: Requires gas pipeline or tank; fuel price volatility

Fuel: Diesel, heavy oil, waste oil

- Works where gas is unavailable

- Stable heating

Cons: Higher emissions; soot cleaning required

Fuel: Pellets, chips, rice husk, crop waste

- Eco-friendly

- Lowest fuel cost

- Perfect for agricultural regions

Cons: Requires more space; ash handling

- Lowest fuel price

- High emissions & regulatory limits

- Zero on-site emissions

- High steam quality

- High operating cost

5. Efficiency Factors of a 6 Ton Boiler

5.1 Burner Efficiency

Advanced modulating burners reduce waste and improve stability.

5.2 Boiler Design

- Condensing units recover waste heat

- Enhanced heat surfaces reduce fuel use

5.3 Water Quality

Poor water quality = scale buildup → 10–15% efficiency loss.

5.4 Insulation & Heat Loss

Proper insulation significantly improves efficiency.

5.5 Maintenance Practices

Routine maintenance extends boiler lifespan and performance.

6. Operating Cost of a 6 Ton Boiler

Fuel Consumption (Approximate)

- Gas: 400–450 m³/h

- Diesel: 380–420 L/h

- Biomass: 1000–1300 kg/h

- Coal: 800–900 kg/h

Other Costs

- Maintenance

- Electrical components

- Water treatment chemicals

7. How to Choose the Right 6 Ton Steam Boiler

7.1 Fuel Availability

Select a fuel with stable supply and competitive pricing.

7.2 Steam Quality Requirements

Pharmaceutical and food industries require high-purity steam.

7.3 Environmental Regulations

Regions with strict standards prefer gas or biomass boilers.

7.4 Operating Budget

Balance upfront investment with long-term fuel savings.

7.5 Manufacturer Reliability

- Certifications

- After-sales service

- Spare parts availability

- Real industrial project cases

8. Installation & Maintenance Considerations

8.1 Installation Requirements

- Adequate boiler room space

- Proper ventilation

- Correct chimney design

- Water treatment systems

8.2 Essential Auxiliary Equipment

- Economizer

- Deaerator

- Water softener / RO unit

- Feedwater pumps

- Dust removal & desulfurization (for coal/biomass)

8.3 Routine Maintenance Checklist

- Clean burner monthly

- Inspect smoke tubes

- Test safety valves

- Check water quality

9. Conclusion

A 6-ton industrial steam boiler is a highly flexible and efficient solution for a wide range of industrial applications. With multiple fuel options, advanced control systems, and customizable configurations, it remains a preferred choice for factories worldwide.

Choosing the right model depends on fuel availability, cost, emissions requirements, and industry-specific needs. When properly installed and maintained, a 6-ton steam boiler can operate reliably for over 20 years while keeping production lines running at optimal efficiency.

If you have any needs, please contact us in your convenience.

View Reviews of our Customer

"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"Fangkuai's auxiliary equipment has made my boiler system even better. The quality of the equipment is exceptional and the prices are very reasonable. The equipment has helped improve the efficiency and performance of my boiler system, which has led to significant cost savings. I highly recommend Fangkuai's auxiliary equipment to anyone in need of high-quality boiler accessories."

Maryk

UK