What Are Oil-Fired Steam Boilers For Sale?

Oil-fired steam boilers are heating systems that use oil as a fuel source to heat water and produce steam. The steam is then used for various applications, such as heating buildings or powering industrial processes. The oil is burned in a combustion chamber within the boiler, and the heat produced by the burning oil is used to heat water and create steam. Oil-fired steam boilers are known for their high efficiency, reliability, and ease of maintenance, and are commonly used in industries such as chemical, petrochemical, pharmaceutical, and food and beverage processing.

Working Principle

The working principle of oil-fired steam boilers involves the combustion of oil in a combustion chamber within the boiler. The heat produced by the burning oil is then used to heat water, which creates steam. The steam is then transported through pipes to various locations, where it is used for heating or other applications. Oil-fired steam boilers are typically equipped with a pressure control system, water level control system, and safety devices to ensure safe and efficient operation. Regular maintenance and cleaning of the combustion chamber, heat exchanger, and other components are necessary to ensure optimal performance and efficiency.

Oil Fired Steam Boiler Main Components

The main components of an oil-fired steam boiler include:

- Combustion Chamber: This is where the oil is burned to produce heat.

- Heat Exchanger: The heat exchanger is where the heat from the combustion process is transferred to the water, which is converted into steam.

- Water Level Control System: This system is used to monitor and control the water level in the boiler to prevent damage to the heat exchanger and ensure safe operation.

- Pressure Control System: The pressure control system regulates the pressure of the steam to ensure it remains within safe operating limits.

- Safety Devices: Safety devices, such as relief valves and low water cutoff switches, are installed to prevent accidents and protect the boiler and surrounding equipment.

- Fuel Oil System: The fuel oil system delivers oil to the burner for combustion.

- Control Panel: The control panel is used to monitor and control the operation of the boiler.

Oil-Fired Steam Boiler Advantages

Oil-fired steam boilers have several advantages, including:

- High Efficiency: Oil-fired steam boilers have a high-efficiency rating, which means they can convert a large percentage of the fuel into heat.

- Reliable Operation: Oil-fired steam boilers are known for their reliability and durability and can operate for long periods without requiring maintenance.

- Easy Maintenance: Oil-fired steam boilers are easy to maintain and repair, which can help reduce downtime and maintenance costs.

- Versatility: Oil-fired steam boilers can be used for a wide range of applications, including heating buildings, powering industrial processes, and generating electricity.

- Fuel Availability: Oil is widely available and can be sourced from a variety of locations, making it a reliable and accessible fuel source.

- Clean Burning: Modern oil-fired steam boilers produce less pollution and emissions compared to older models, making them an environmentally friendly heating option.

Oil-Fired Steam Boilers Vs Other Boiler

When it comes to choosing a heating system, oil-fired steam boilers have some advantages over other types of boilers, such as:

- Efficiency: Oil-fired steam boilers have a high-efficiency rating, which means they can convert a large percentage of the fuel into heat. This can result in lower fuel consumption and lower operating costs compared to other types of boilers.

- Reliability: Oil-fired steam boilers are known for their reliability and durability, and can operate for long periods without requiring maintenance.

- Versatility: Oil-fired steam boilers can be used for a wide range of applications, including heating buildings, powering industrial processes, and generating electricity.

- Clean Burning: Modern oil-fired steam boilers produce less pollution and emissions compared to older models, making them an environmentally friendly heating option.

However, there are also some disadvantages to using oil-fired steam boilers, such as:

- Cost: Oil-fired steam boilers can be more expensive to purchase and install compared to other types of boilers.

- Fuel Availability: While oil is widely available, it can be subject to price fluctuations and supply disruptions.

- Maintenance: While oil-fired steam boilers are generally easy to maintain, they do require periodic cleaning and maintenance to ensure optimal performance and efficiency.

Overall, the choice between oil-fired steam boilers and other types of boilers depends on factors such as the specific application, fuel availability, and budget constraints.

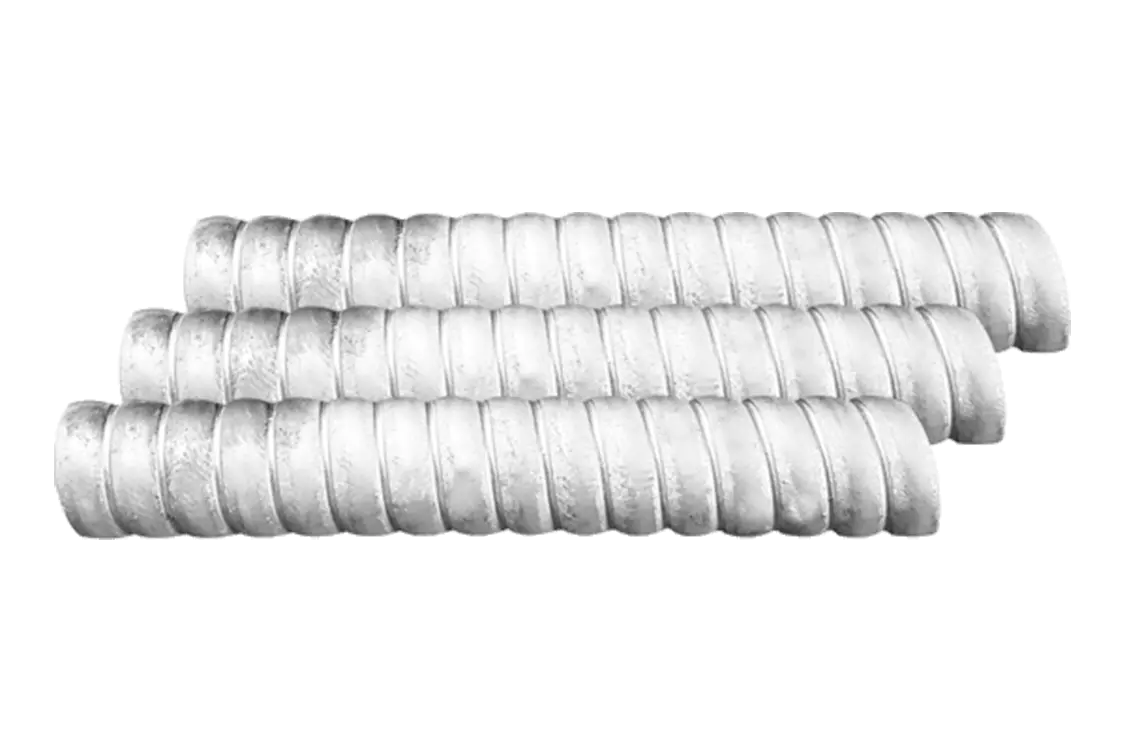

Why Choose Fangkuai Oil Steam Boiler?

If you’re in the market for an oil-fired steam boiler, look no further than Fangkuai Boiler. Our boilers are designed to be efficient, reliable, and versatile, making them ideal for a wide range of industries and applications. With our oil-fired steam boilers, you can enjoy the benefits of clean burning and high efficiency, while also benefiting from the reliability and durability that Fangkuai Boiler is known for. Plus, our boilers are easy to maintain and repair, helping to reduce downtime and maintenance costs. So if you’re looking for a top-of-the-line boiler that you can count on, consider Fangkuai Boiler and experience the difference for yourself.

Oil-Fired Steam Boiler Manufacturers

If you’re in the market for an oil-fired steam boiler, you can’t go wrong with Fangkuai Boiler. As one of the top manufacturers in the industry, we’re dedicated to providing our customers with high-quality, reliable, and efficient heating solutions. Our oil-fired steam boilers are designed to meet the needs of a wide range of industries and applications, from food processing and manufacturing to hospitals and universities. With Fangkuai Boiler, you can enjoy the peace of mind that comes with investing in a top-of-the-line heating system that will keep your operations running smoothly and efficiently for years to come. So why wait? Visit our website today to learn more about our oil-fired steam boilers and how they can benefit your business.

Oil-Fired Steam Boiler Goods Delivery

Based on good quality and decades of experience, the equipment which is manufactured by FANGKUAI was exported to different countries. The equipment will be packed and loaded in our factory, and then be shipped to our clients safe and sound.