Introduction

In modern industries, steam is a core utility used for heating, processing, and power generation. Choosing the right industrial steam boiler is crucial to meet process requirements, control costs, and comply with environmental rules. This guide explains the main boiler types, how they operate, and the industrial applications best suited to each type.

What Is an Industrial Steam Boiler?

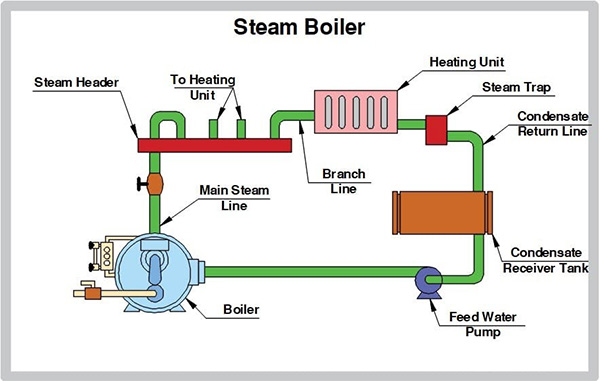

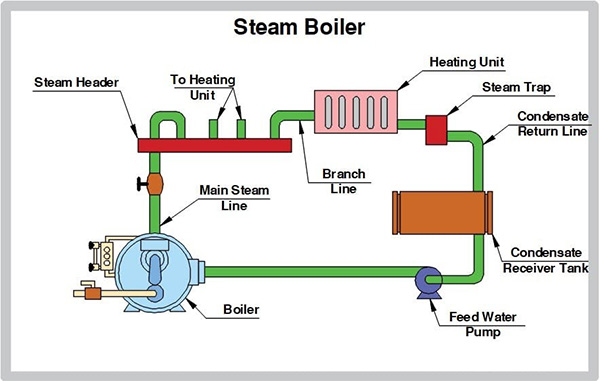

An industrial steam boiler is a pressure vessel that heats water to produce steam for industrial processes. Typical boiler systems include a furnace for combustion (or electrical heating), heat-exchange surfaces, and a drum or shell to collect steam. Steam is used for process heating, sterilization, driving turbines, drying, and many other applications.

Main Types of Industrial Steam Boilers

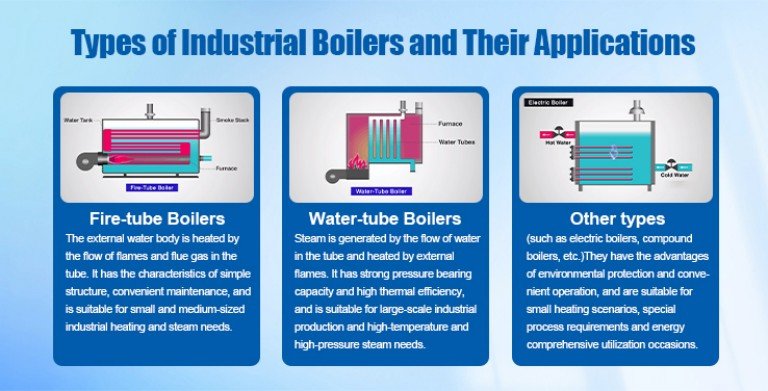

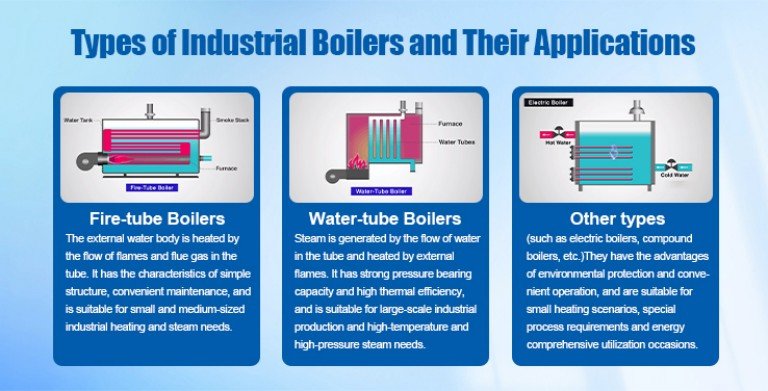

1. Fire-Tube Boilers

Fire-tube boilers pass hot combustion gases through tubes surrounded by water. Heat transfers from the gas to the water, producing steam.

- Advantages: Simple design, easy maintenance, lower capital cost.

- Limitations: Lower pressure/steam capacity compared with water-tube designs.

- Typical applications: Small to medium-size plants, food processing, laundries, commercial heating.

Water-tube boilers flow water through tubes heated externally by combustion gases. They handle higher pressures and larger steam volumes.

- Advantages: High pressure and capacity, fast steam generation, improved safety at high pressure.

- Limitations: Higher initial cost and more complex maintenance.

- Typical applications: Power plants, chemical and petrochemical industries, pulp & paper mills.

3. Electric Steam Boilers

Electric boilers use electric resistance or electrode heating to generate steam instead of burning fuel.

- Advantages: Zero combustion emissions on site, compact, quiet operation.

- Limitations: Operating cost depends on electricity price; less suitable where electricity is expensive.

- Typical applications: Hospitals, laboratories, pharmaceutical and food industries where clean steam and emissions-free operation are required.

Biomass boilers burn organic fuels (wood chips, pellets, agricultural residues) to produce steam.

- Advantages: Renewable fuel source, potentially lower net CO₂ footprint, can use local waste streams.

- Limitations: Fuel handling and storage complexity; variable fuel quality.

- Typical applications: Agricultural processing, district heating with renewable targets, sustainable manufacturing sites.

These boilers combust natural gas, diesel, or heavy fuel oil to generate steam and are widely used across industries.

- Advantages: High thermal efficiency, fast startup, mature technology.

- Limitations: Fuel cost volatility; emissions must be managed per regulations.

- Typical applications: Manufacturing plants, refineries, food & beverage processing, textile mills.

Comparing Boiler Types — Key Considerations

When selecting a boiler, compare types by:

- Steam capacity & pressure required by process equipment.

- Fuel availability & cost (gas, oil, biomass, electricity).

- Efficiency & operating cost, including potential for waste heat recovery.

- Maintenance complexity and local technical support capability.

- Environmental & emissions regulations in your jurisdiction.

Industrial Applications of Steam Boilers

Steam boilers serve diverse industries. Typical applications include:

- Power generation: Water-tube boilers feed steam turbines in thermal power plants.

- Food & beverage: Sterilization, cooking, drying and process heating.

- Textile & paper: Steam for dyeing, drying, pulp processing.

- Chemical & petrochemical: Process heating, distillation, reaction control.

- Pharmaceutical & healthcare: Clean steam for sterilization and controlled processes.

How to Choose the Right Industrial Steam Boiler

- Assess process steam demand: Calculate peak and average steam loads (kg/h or lb/h).

- Determine pressure & steam quality: Some processes require superheated or very dry steam.

- Select fuel strategy: Evaluate fuel cost, reliability, and sustainability goals (e.g., biomass or electrification).

- Consider space & installation constraints: Boiler room size, access, and stack/venting requirements.

- Plan for maintenance & spare parts: Local service capability reduces downtime risk.

- Factor in emissions compliance: Emission controls or low-NOx options may be required.

The Future of Industrial Steam Boilers

Industrial boilers are evolving with a focus on efficiency and sustainability. Key trends include:

- Waste heat recovery & economizers to capture exhaust energy.

- Low-emission burners and exhaust treatment to meet stricter air quality rules.

- Integration with renewables (biomass co-firing, solar thermal preheat).

- Digital monitoring & IoT for predictive maintenance and performance optimization.

Conclusion

Choosing the right industrial steam boiler depends on your process needs, fuel strategy, space, and regulatory environment. Fire-tube boilers fit smaller operations, water-tube designs suit high-pressure, high-capacity needs, electric boilers offer clean on-site steam, and biomass or gas/oil-fired units provide flexibility based on fuel availability. Carefully evaluating demand, efficiency, and lifecycle costs will help you select a boiler that delivers reliable performance and the best return on investment.

If you have any needs, please contact us in your convenience.

View Reviews of our Customer

"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"Fangkuai's auxiliary equipment has made my boiler system even better. The quality of the equipment is exceptional and the prices are very reasonable. The equipment has helped improve the efficiency and performance of my boiler system, which has led to significant cost savings. I highly recommend Fangkuai's auxiliary equipment to anyone in need of high-quality boiler accessories."

Maryk

UK"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt