Introduction

In industrial production, heating systems, and ship power, boilers are the core thermal equipment that converts water into steam or hot water by burning fuel to supply energy for various processes. In the face of various boiler types, water tube boilers and fire tube boilers have become the focus due to their wide range of applications, and the two are significantly different in structure, performance and applicable scenarios. This article will analyze the principles, differences, advantages and disadvantages of the two types of boilers to help you make an accurate choice.

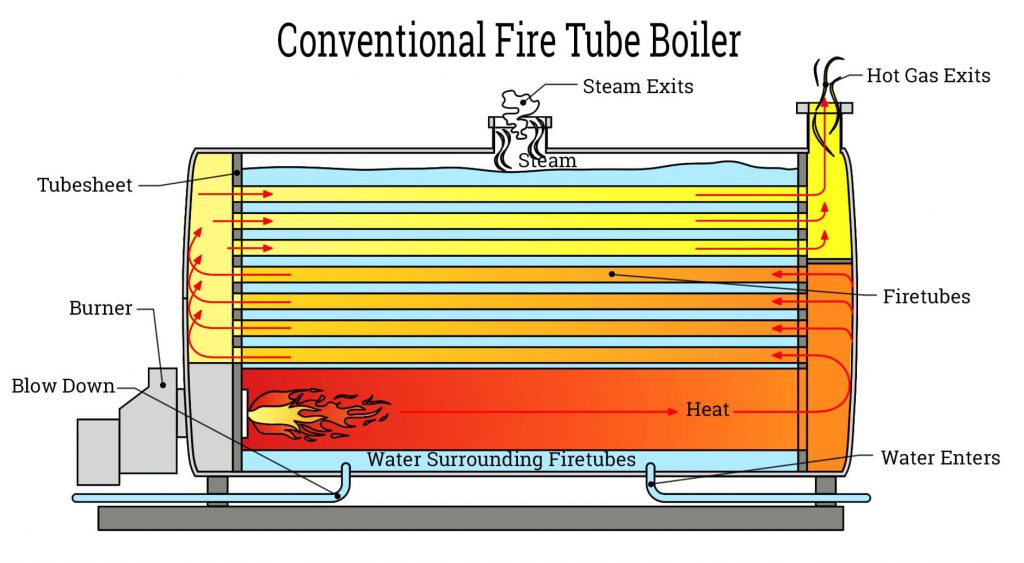

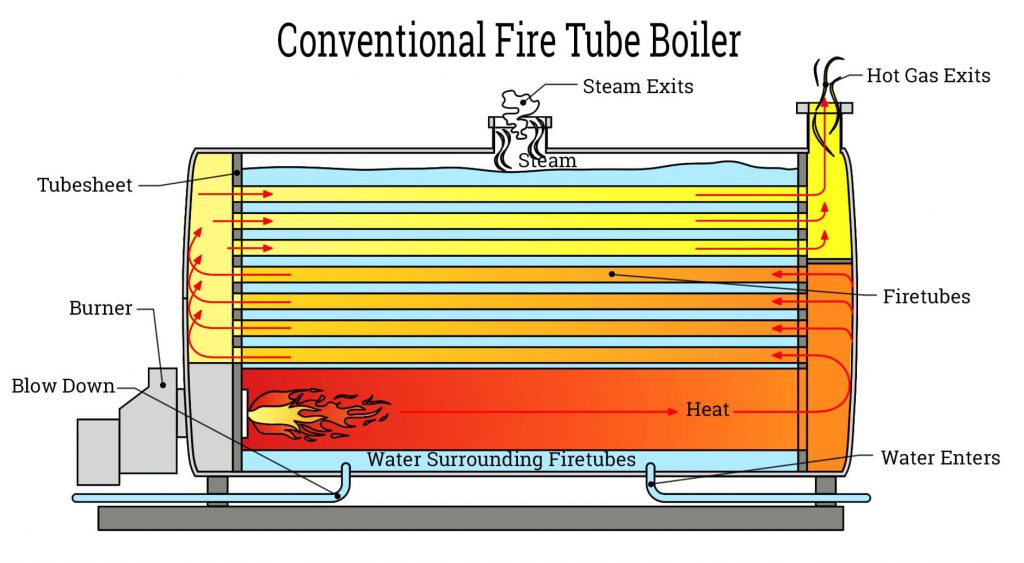

What is a Fire Tube Boiler?

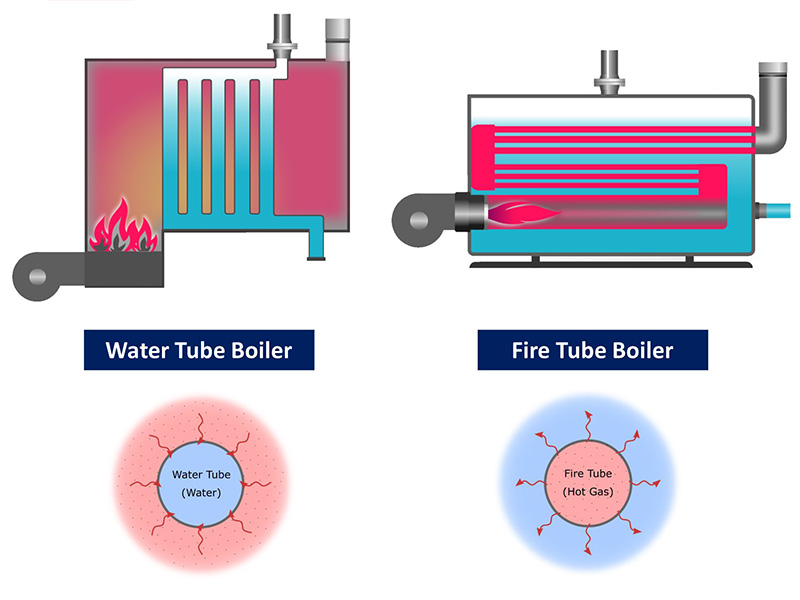

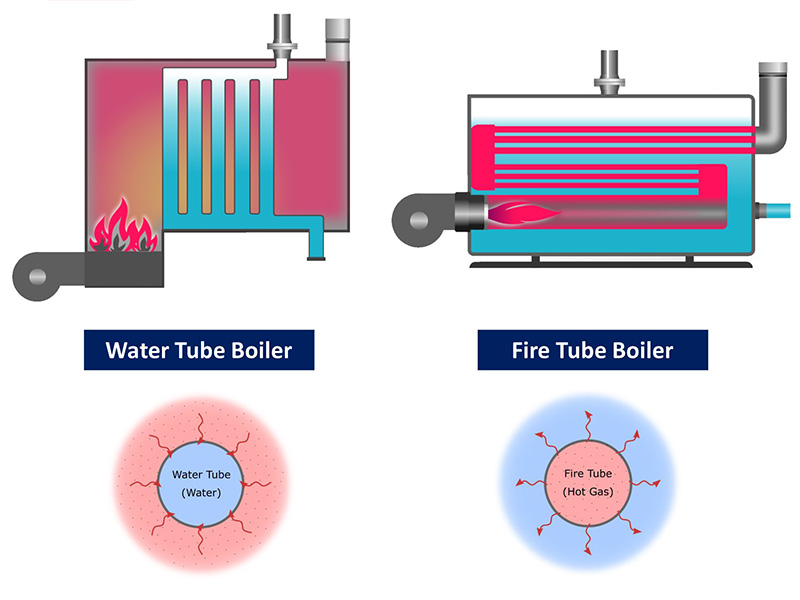

Fire tube boiler is a traditional boiler type, the core structure is the furnace tube and fire tube. The combustion chamber is located inside the furnace tube, and the high-temperature flue gas generated by fuel combustion flows in a number of fire tubes that run through the water space of the boiler, and the water is wrapped outside the fire tube, and the heat conduction and convection heat transfer of the fire tube wall are heated and vaporized. Its design is simple, relying on the basic heat transfer principle to work, and the overall structure is built around the core logic of “flue gas inside the pipe and water outside the pipe”.

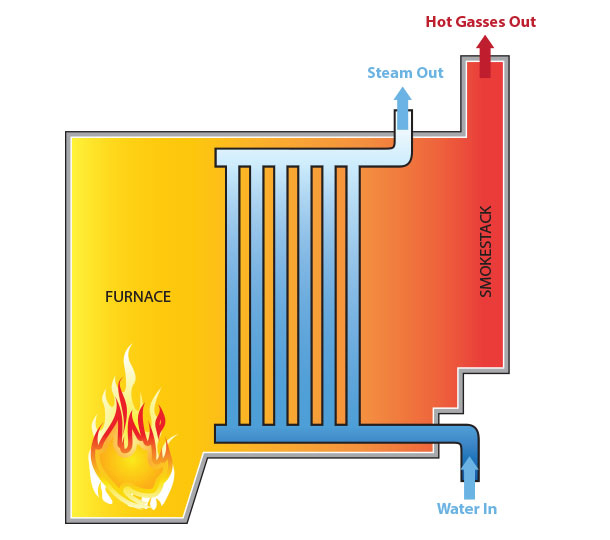

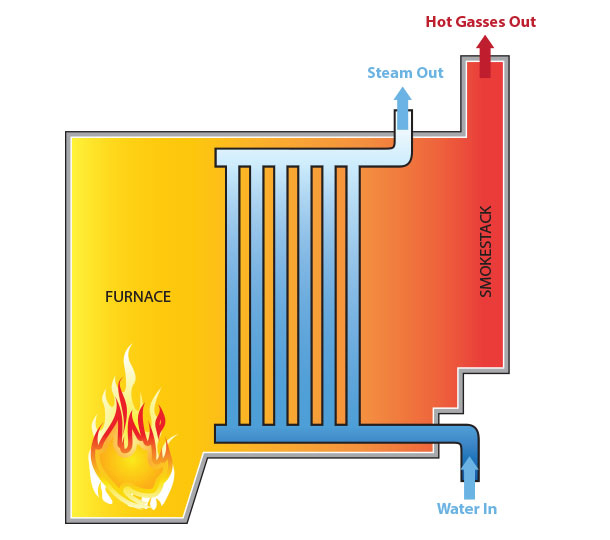

What is a Water Tube Boiler?

The water tube boiler adopts the opposite structure design of the fire tube boiler, and the core is “water inside the tube and flue gas outside the pipe”. The boiler body consists of multiple curved or spirally arranged water pipes to increase the heat transfer area. The high-temperature flue gas generated by combustion flows outside the water pipe, and the heat is transferred to the water circulating in the pipe through the pipe wall, causing the water to heat up and produce steam. Its design is highly flexible, and the arrangement and quantity of water pipes can be adjusted according to actual needs to adapt to different working conditions.

Structural design

The fire tube boiler has a simple structure, with the furnace tube, fire tube and water space as the core, the fire tube runs through the water space, and the flue gas transfers heat in the tube. The water tube boiler is mainly based on a number of special-shaped water pipes, the water circulates inside the pipe, and the flue gas washes the heat exchange outside the pipe, which is more complex in structure but the heat exchange layout is more efficient.

Thermal efficiency

Due to the large heat exchange area and reasonable flue gas flow path, the thermal efficiency of water tube boilers is generally high, usually above 80%, and the advanced design can be close to 90%; The heat tube boiler is limited by a small heat exchange area and a large flue gas flow resistance, and the thermal efficiency is relatively low, mostly between 70% and 80%, and the heat utilization rate gap is obvious.

Security

The fire tube boiler has a large water capacity, strong buffering ability when the pressure changes, and is more stable in the face of sudden pressure fluctuations. The water pipe boiler has a small water capacity, but the structure is compact, the water pipe wall thickness is thinner, the pressure response is faster, and it is generally equipped with advanced pressure sensors and automatic control systems, which can quickly intervene in abnormal situations and take more active safety protection.

Application Scenarios

Fire tube boilers are suitable for scenarios with low steam demand and low thermal efficiency requirements, such as small processing plants, local heating, etc; Due to its high efficiency and compactness, water tube boilers are suitable for large-scale industrial production, ship power, urban central heating and other occasions with strict requirements for thermal efficiency and space utilization.

Advantages of Fire Tube Boilers

Lower cost

The simple structure reduces manufacturing difficulty and material consumption, and the initial procurement and installation costs are significantly lower than that of water tube boilers, making them more economically attractive to small and medium-sized enterprises with limited budgets.

Simple maintenance

With few components and intuitive layout, the fire pipe can be easily disassembled, cleaned or replaced, the control system has a low operating threshold, and daily maintenance can be completed without professional technicians, and the long-term operation and maintenance cost is controllable.

Strong pressure buffering ability

The large water capacity allows it to reduce the pressure shock through the water body’s own buffer when the pressure changes caused by load fluctuations, and the operating stability has obvious advantages under low pressure conditions.

Advantages of Water Tube Boilers

High thermal efficiency

The arrangement of special-shaped water pipes greatly increases the heat exchange area, the contact between flue gas and water pipes is more sufficient, and the heat loss is less, and long-term operation can significantly reduce fuel consumption, especially in high-load scenarios.

Compact structure

The design with tube bundle as the core can achieve efficient heat exchange in a limited space, suitable for ships, large factories and other space-constrained occasions, and has stronger adaptability to the site during installation.

High security

In addition to the active monitoring and control system, the pressure is distributed on multiple water pipes and containers, avoiding the risk concentration of a single pressure-bearing component, and the explosion resistance and accident warning ability are better.

Which Boiler Should You Choose?

The choice should be closely related to the actual needs: if the steam demand is small, the thermal efficiency requirements are average, and the budget is limited, and the maintenance manpower is insufficient (such as small food processing plants, shop heating), the low-cost and easy-maintenance characteristics of the fire tube boiler are more suitable; If you need high-pressure and high-capacity steam, pursue high energy savings, or have limited installation space (such as large chemical plants, thermal power plants, ship power systems), the efficiency, compactness, and safety of water tube boilers are the better solution.

Conclusion

There is no absolute advantage or disadvantage between water tube boilers and fire tube boilers, only different adaptation scenarios. The fire tube boiler is based on the small, intermittent low-pressure demand scenario with “simple economy”; Water tube boilers dominate the field of large-scale, continuous and high-parameter applications with “high efficiency and compactness”. When choosing, it is necessary to comprehensively weigh factors such as steam parameters, budget, space, operation and maintenance capabilities, and other factors.

If you have any needs, please contact us in your convenience.

View Reviews of our Customer

"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"Fangkuai's auxiliary equipment has made my boiler system even better. The quality of the equipment is exceptional and the prices are very reasonable. The equipment has helped improve the efficiency and performance of my boiler system, which has led to significant cost savings. I highly recommend Fangkuai's auxiliary equipment to anyone in need of high-quality boiler accessories."

Maryk

UK"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China