Introduction

Wood steam boilers use biomass fuel—logs, chips or pellets—to generate steam for space heating, process heat or hot water. They are especially valuable in off-grid, rural or sustainability-focused projects because they rely on a renewable fuel source and can reduce dependence on fossil fuels. This guide explains how wood steam boilers work, the environmental and economic benefits, the main types available, how to choose the right system, and practical maintenance and safety advice so you get reliable, efficient performance.

How Wood Steam Boilers Work — The Basics

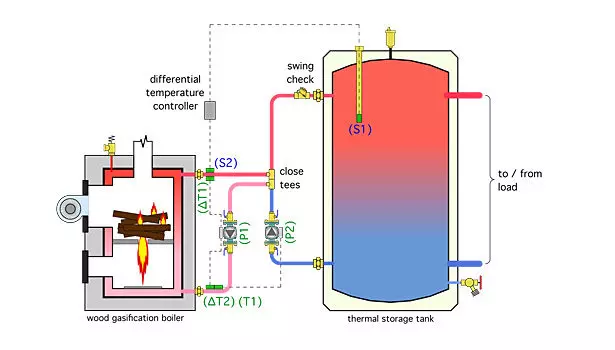

A wood steam boiler converts the chemical energy stored in wood into thermal energy and then into steam:

- Combustion chamber: Wood fuel is burned in a firebox or combustion chamber, producing hot flue gases.

- Heat transfer: Heat from the gases transfers through heat-exchange surfaces into water contained in the boiler.

- Steam generation: As water reaches boiling point under pressure, it becomes steam.

- Steam distribution: The steam is piped to radiators, process equipment or a turbine (for power).

- Condensation & return (optional): Condensed steam (condensate) may be returned to the boiler as feedwater, improving overall efficiency.

Compared with hot-water systems, steam boilers operate at higher pressures and require specific controls and operator training to ensure safe operation.

Environmental & Economic Advantages

- Renewable fuel: Wood is a biomass resource; sustainably harvested wood releases roughly the CO₂ that the tree absorbed during growth—making it close to carbon-neutral when managed responsibly.

- Lower fuel cost potential: In many regions wood (especially residue streams or locally sourced fuel) is cheaper than oil, propane or electricity. Using local biomass can also shield you from fossil fuel price volatility.

- Energy density and efficiency: Modern wood steam boilers and pellet systems are designed to extract more heat from fuel than older models—so you get strong thermal output per unit of fuel.

- Local economic benefit: Buying local wood or using onsite residues supports local forestry/agriculture and reduces transport emissions.

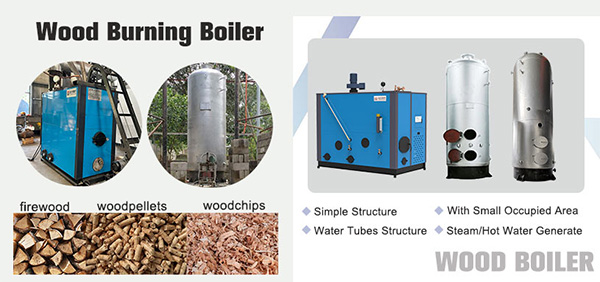

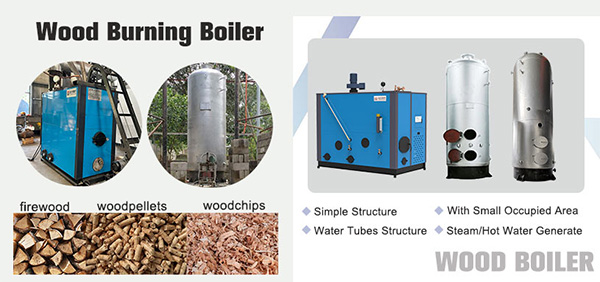

Main Types of Wood Steam Boilers

Outdoor Wood Boilers

Installed outside the building; heat is piped in via insulated lines.

Pros: Saves indoor space and reduces indoor emissions risk.

Cons: Must be weather-protected; heat loss in pipe runs can be an issue if not well insulated.

Indoor Wood Boilers

Installed inside (basement or utility room).

Pros: Shorter distribution piping, easier servicing in winter.

Cons: Requires adequate venting and fire safety clearances.

Wood Pellet Boilers

Burn manufactured pellets rather than logs. Pellets provide consistent fuel quality and allow automated feeding systems.

Pros: High combustion efficiency, easier storage, lower operator time.

Cons: Requires pellet supply chain and storage space.

Log / Cordwood Boilers

Rely on manual loading of split logs. Good for low-tech, off-grid settings but require regular tending.

When choosing a type, consider fuel availability, automation needs, space and how much operator time you can commit.

How to Choose the Right Wood Steam Boiler

- Match capacity to demand: Calculate peak and average steam or heat loads. Oversizing wastes fuel; undersizing leaves you short on cold days.

- Fuel strategy: Choose equipment optimized for the fuel you can easily source (pellets, chips, or logs).

- Automation level: Pellet boilers allow automated feed and ash removal; manual log boilers require more attention.

- Efficiency & emissions: Look for secondary combustion designs, large heat-exchange surfaces, and low-emission certification.

- Installation & venting: Plan proper flues and corrosion-resistant materials for condensing designs.

- Service & warranty: Buy from reputable manufacturers with local maintenance support.

Operation, Maintenance & Safety Best Practices

- Daily / weekly tasks: Check fuel level, remove ash, inspect the flame and combustion quality.

- Periodic tasks: Clean heat exchangers, check gaskets and refractory, and test safety valves and controls.

- Water quality: Maintain feedwater chemistry and prevent corrosion and scaling.

- Safety: Regularly inspect pressure relief valves, maintain correct water levels, ensure proper ventilation and chimney function.

- Operator training: Provide clear procedures and emergency shutdown instructions.

Cost Considerations

- Capital cost: Ranges from simple outdoor log boilers to advanced pellet condensing models. Include installation and storage costs.

- Operating cost: Depends on fuel price, efficiency, and maintenance. Reusing condensate and insulating pipes improves efficiency.

- Payback: In areas with cheap or local biomass, the payback period versus fossil fuels can be attractive.

Common Concerns & How to Address Them

- Emissions: Choose low-emission boilers and follow proper combustion practices.

- Fuel variability: Use dry, uniform fuel. Consider pellets if wood supply quality varies.

- Space & installation: Plan for ash removal access, safe storage, and adequate chimney height.

Conclusion

Wood steam boilers offer a renewable, potentially cost-effective heating solution for those seeking sustainability or energy independence. Choosing the right system requires assessing fuel type, capacity, automation, and maintenance needs. Properly installed and maintained wood steam boilers deliver reliable heat, lower energy costs, and a reduced carbon footprint.

If you have any needs, please contact us in your convenience.

Quick FAQ

Q: Are wood steam boilers carbon neutral?

A: When sourced sustainably and burned efficiently, wood can be close to carbon-neutral because the CO₂ emitted equals what the tree absorbed during growth.

Q: Can I automate a wood boiler?

A: Yes. Pellet boilers often feature automatic fuel feed and ash removal systems.

Q: Do wood boilers need regular servicing?

A: Yes. Annual professional inspections and periodic cleaning ensure both safety and efficiency.

View Reviews of our Customer

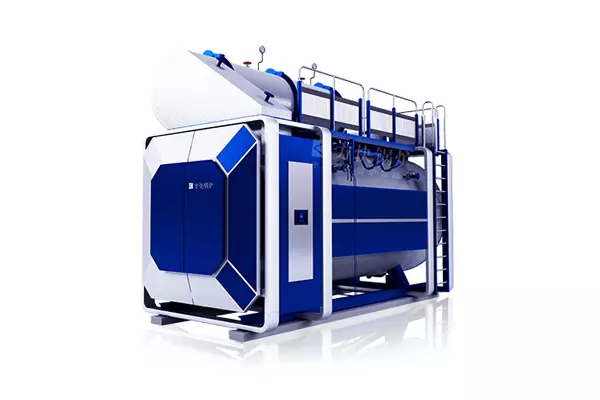

"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"Fangkuai's auxiliary equipment has made my boiler system even better. The quality of the equipment is exceptional and the prices are very reasonable. The equipment has helped improve the efficiency and performance of my boiler system, which has led to significant cost savings. I highly recommend Fangkuai's auxiliary equipment to anyone in need of high-quality boiler accessories."

Maryk

UK"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico"Fangkuai's auxiliary equipment has made my boiler system even better. The quality of the equipment is exceptional and the prices are very reasonable. The equipment has helped improve the efficiency and performance of my boiler system, which has led to significant cost savings. I highly recommend Fangkuai's auxiliary equipment to anyone in need of high-quality boiler accessories."

Maryk

UK