A 6 吨 蒸汽锅炉 is one of the most widely used industrial boiler capacities across global manufacturing sectors. With a rated output of 6,000 kg of steam per hour, this boiler size provides a perfect balance between steam demand, 燃油效率, and operational cost. Whether it is used in food production, textile processing, 化学制造, or construction, the 6-ton steam boiler plays a crucial role in providing stable heat and consistent steam supply.

This guide explains how 6-ton steam boilers work, their core applications, available fuel types, 效率因素, and how to choose the right model for your industrial needs.

1. What Is a 6 Ton Industrial Steam Boiler?

A 6-ton steam boiler is an industrial pressure vessel designed to generate steam at a rate of 6 每小时吨. 大多数情况下, these boilers operate under medium pressure, 范围从 1.0 兆帕至 1.6 兆帕, depending on production requirements.

Why 6 吨?

- Matches the steam consumption of medium-scale factories

- More fuel-efficient than 4-ton models

- Lower investment compared to 10-ton or larger boilers

Common Technical Characteristics

- Horizontal fire-tube or 水管 设计

- Fully automatic control system

- 热效率高 (85%–98%)

- Customizable fuel systems: 气体, 油, 生物质, 煤炭

This makes the 6-ton boiler extremely versatile across industries.

2. Key Technical Specifications

2.1 蒸汽容量

- 6,000 kg/h continuous output

- Ideal for high-load production environments

2.2 Operating Pressure Options

- Low pressure: 0.7 兆帕

- Medium pressure: 1.0–1.6 MPa

- High-pressure options available

2.3 热效率

- Standard models: 85%–92%

- High-efficiency/condensing models: 95%–98%

2.4 Structural Design

- Fire-tube boilers for general industries

- Water-tube boilers for chemical or continuous operations

2.5 安全 & Automation

- PLC intelligent control

- Flame monitoring

- Automatic water feeding

- Over-temperature & over-pressure protection

- Real-time display and remote control

3. Industrial Applications of 6-Ton Steam Boilers

Because of their excellent heating capacity and stable output, 6-ton steam boilers are widely used across industries.

- Cooking

- 消毒

- 巴氏杀菌

- Baking & 烘干

- CIP cleaning systems

- 染色

- Printing

- Finishing

- Drying

- Heating reactors

- Distillation

- Solvent extraction

- Pressure control

3.4 Paper and Packaging Industry

- Paper drying

- Corrugated box production

3.5 药物 & Biotechnology

- Clean steam

- 消毒

- Fermentation heating

3.6 Construction Materials

- Concrete curing

- AAC block production

3.7 Agriculture & Farming

- Animal feed production

- Greenhouse heating

- Equipment sterilization

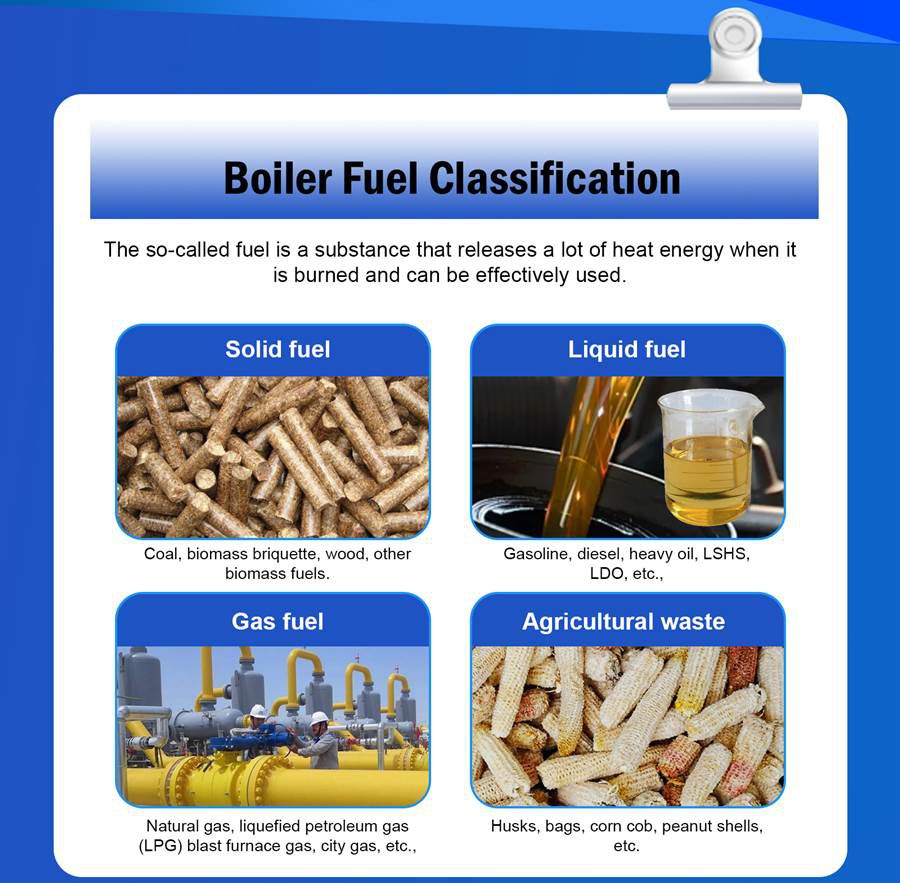

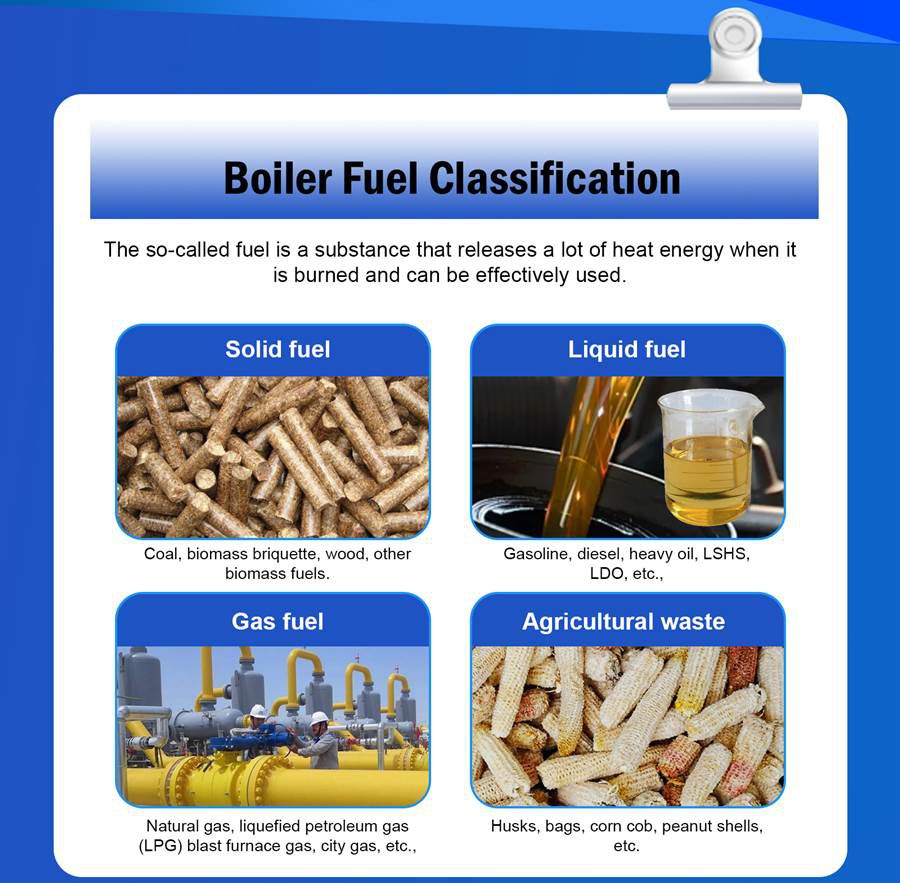

4. Fuel Options for 6 Ton Steam Boilers

燃料: 天然气, 液化石油气, LNG

- 高效率 (取决于 98%)

- Lowest emissions

- 干净的 & 易于维护

局限性: Requires gas pipeline or tank; fuel price volatility

燃料: 柴油机, 重油, waste oil

- Works where gas is unavailable

- Stable heating

缺点: Higher emissions; soot cleaning required

燃料: 颗粒, 筹码, rice husk, crop waste

- 环保的

- Lowest fuel cost

- Perfect for agricultural regions

缺点: Requires more space; ash handling

- Lowest fuel price

- High emissions & regulatory limits

- Zero on-site emissions

- 蒸汽质量高

- High operating cost

5. Efficiency Factors of a 6 Ton Boiler

5.1 Burner Efficiency

Advanced modulating 燃烧器 reduce waste and improve stability.

5.2 Boiler Design

- Condensing units recover waste heat

- Enhanced heat surfaces reduce fuel use

5.3 Water Quality

Poor water quality = scale buildup → 10–15% efficiency loss.

5.4 Insulation & Heat Loss

Proper insulation significantly improves efficiency.

5.5 Maintenance Practices

Routine maintenance extends boiler lifespan and performance.

6. Operating Cost of a 6 Ton Boiler

燃油消耗 (Approximate)

- 气体: 400–450 m³/h

- 柴油机: 380–420 L/h

- 生物质: 1000–1300 kg/h

- 煤炭: 800–900 kg/h

Other Costs

- 维护

- Electrical components

- Water treatment chemicals

7. How to Choose the Right 6 吨蒸汽锅炉

7.1 燃料可用性

Select a fuel with stable supply and competitive pricing.

7.2 Steam Quality Requirements

Pharmaceutical and food industries require high-purity steam.

7.3 Environmental Regulations

Regions with strict standards prefer gas or biomass boilers.

7.4 Operating Budget

Balance upfront investment with long-term fuel savings.

7.5 Manufacturer Reliability

- Certifications

- After-sales service

- Spare parts availability

- Real industrial project cases

8. 安装 & 维护注意事项

8.1 安装要求

- Adequate boiler room space

- 适当通风

- Correct chimney design

- 水处理系统

8.2 Essential Auxiliary Equipment

- 节能器

- Deaerator

- Water softener / RO unit

- 给水泵

- Dust removal & desulfurization (for coal/biomass)

8.3 Routine Maintenance Checklist

- Clean burner monthly

- Inspect smoke tubes

- Test safety valves

- Check water quality

9. 结论

A 6-ton industrial steam boiler is a highly flexible and efficient solution for a wide range of industrial applications. With multiple fuel options, advanced control systems, and customizable configurations, it remains a preferred choice for factories worldwide.

Choosing the right model depends on fuel availability, 成本, emissions requirements, and industry-specific needs. When properly installed and maintained, a 6-ton steam boiler can operate reliably for over 20 years while keeping production lines running at optimal efficiency.

如果您有任何需求, 请在您方便的时候联系我们.

V查看我们客户的评论

"方快的热水锅炉质量让我印象深刻. 它经久耐用,超出了我的预期. 安装过程也很顺利,客服态度也很好. 热水锅炉操作维护非常方便, 能源效率显着. 强烈推荐方快的热水器。"

杰克

澳大利亚"我们化工厂一直在使用方快导热油锅炉多年,从未让我们失望过. 锅炉非常耐用,可以承受恶劣的条件. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 方快的导热油锅炉是一流的,我强烈推荐给任何需要可靠供暖解决方案的人。"

张

中国"方快的客户服务是一流的. 他们帮助我选择了满足我需求的完美锅炉,并在整个过程中提供了大力支持. 安装过程也很顺利,锅炉超出了我的预期. 非常易于使用和维护, 能源效率显着. 我向任何需要可靠高效供暖解决方案的人强烈推荐方快的产品。"

娟

墨西哥"方快的客户服务是一流的. 他们帮助我选择了满足我需求的完美锅炉,并在整个过程中提供了大力支持. 安装过程也很顺利,锅炉超出了我的预期. 非常易于使用和维护, 能源效率显着. 我向任何需要可靠高效供暖解决方案的人强烈推荐方快的产品。"

娟

墨西哥"方快的辅助设备让我的锅炉系统更上一层楼. 设备质量卓越,价格非常合理. 该设备帮助提高了我的锅炉系统的效率和性能, 这导致显着的成本节约. 我向任何需要优质锅炉配件的人强烈推荐方快的辅助设备。"

马里克

英国"方快导热油锅炉操作维护非常方便. 它帮助我们节省了维护时间和金钱, 这导致显着的成本节约. 材料的质量和锅炉的构造非常出色. 它也非常节能, 这帮助我们节省了能源费用. 强烈推荐方快的导热油锅炉 ."

艾伦

巴西"方快的蒸汽发生器非常适合我的小生意. 它非常易于使用,需要最少的维护. 它也非常节能, 这帮助我节省了能源费用. 方快的客服也很好. 他们反应灵敏,乐于助人. 强烈推荐方快的蒸汽发生器。"

艾哈迈德

埃及"我们化工厂一直在使用方快导热油锅炉多年,从未让我们失望过. 锅炉非常耐用,可以承受恶劣的条件. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 方快的导热油锅炉是一流的,我强烈推荐给任何需要可靠供暖解决方案的人。"

张

中国"方快的客户服务是一流的. 他们帮助我选择了满足我需求的完美锅炉,并在整个过程中提供了大力支持. 安装过程也很顺利,锅炉超出了我的预期. 非常易于使用和维护, 能源效率显着. 我向任何需要可靠高效供暖解决方案的人强烈推荐方快的产品。"

娟

墨西哥