Introduction

As energy prices and carbon regulations evolve, biomass boilers remain a strong option for homes, commercial buildings and industrial sites seeking renewable heat. This guide breaks down the total cost of biomass systems in 2025 — from unit price to installation, fuel and maintenance — and shows how to evaluate ROI and reduce long-term costs.

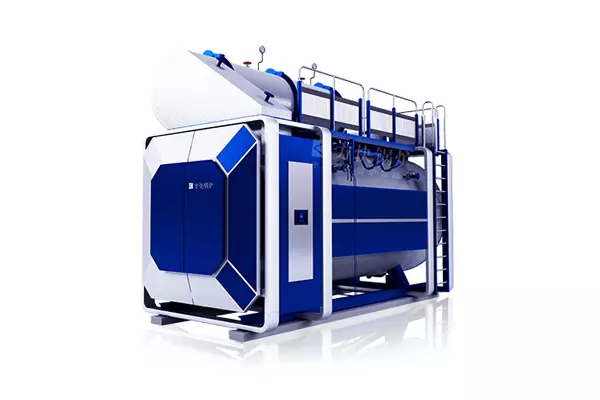

What Is a Biomass Boiler?

A biomass boiler burns organic fuel such as wood pellets, wood chips, briquettes or agricultural residues to produce hot water or steam. Biomass is considered renewable when sourced sustainably and can deliver lower lifecycle carbon emissions compared with fossil fuels.

Typical applications range from domestic heating and hot water to large industrial steam plants used in food processing, textiles, chemicals and manufacturing.

Biomass Boiler Cost in 2025: Quick Price Overview

Costs vary widely by capacity, automation level and site requirements. The table below gives typical price bands for 2025:

| Boiler Type |

Typical Price Range (2025) |

| Residential biomass boiler |

$7,000 – $18,000 |

| Commercial biomass boiler |

$20,000 – $60,000 |

| Industrial biomass steam boiler |

$80,000 – $350,000+ |

Key point: costs rise steeply with capacity and the level of automation (fuel handling, ash removal, emissions controls).

Factors That Influence Biomass Boiler Cost

Boiler size & capacity

Capacity (kW or tonnes/hr) is the primary cost driver. Small domestic units cost far less than industrial steam boilers that must meet higher pressure and output specifications.

Fuel type

Pellets, chips and briquettes differ in price, storage and feed requirements. Pellet systems are usually more automated and more costly upfront but simpler to operate.

System design & equipment

Automatic feeding, silos, conveyors, emission control (cyclones, bag filters), and heat recovery add to capital cost but can lower operating expenses.

Installation complexity

Retrofitting an existing plant costs less than full new-builds that require foundations, chimneys, large silos and significant civil work.

Manufacturer & origin

European-built boilers typically cost more than many Asian models but may include longer warranties, higher automation and stricter certification.

Full Breakdown of Total Biomass Boiler Costs

Below is a typical cost decomposition to help you budget a project.

Boiler unit price

- Residential pellet boiler: $4,000–$10,000

- Commercial chip boiler: $15,000–$40,000

- Industrial steam boiler: $70,000–$300,000+

Installation cost

- Domestic installations: $2,000–$7,000

- Commercial: $5,000–$20,000

- Industrial: $30,000–$120,000+ (foundations, piping, crane, commissioning)

Fuel storage & handling

- Small pellet hopper: $1,000–$5,000

- Feeding screws / augers: $1,500–$8,000

- Industrial silos: $10,000–$40,000

- Conveyors / elevators: $5,000–$25,000

Operation & maintenance (annual)

Expect typical annual O&M of 2–5% of equipment value, covering service visits, spare parts, ash management and routine labour.

Annual fuel cost

Fuel bills depend on consumption and local prices. Example ranges in 2025 (approximate):

- Wood pellets: $180–$420 / ton (region-dependent)

- Wood chips: $60–$140 / ton

- Agricultural residues: $20–$80 / ton

Biomass Fuel Market Snapshot (2025)

Fuel prices are volatile and region-specific. 2025 approximate ranges:

- Wood pellets: North America $180–$280/ton; Europe $300–$420/ton.

- Wood chips: $60–$140/ton — best for large industrial boilers.

- Agricultural residues: $20–$80/ton — low-cost but variable quality.

Note: sourcing local fuel and securing long-term contracts can stabilise costs and improve project economics.

Is a Biomass Boiler Worth It in 2025?

Pros

- Lower fuel cost compared with oil/gas in many regions

- Renewable and potentially carbon-neutral if sustainably sourced

- Strong options for large steam users — fast payback in energy-intensive sites

- Eligible for subsidies and incentives in some jurisdictions

Cons

- High upfront capital expenditure

- Requires space for storage and handling

- Fuel supply logistics must be secure

Typical payback estimates

- Residential: ~5–9 years (depending on fuel savings and incentives)

- Commercial: ~4–7 years

- Industrial: ~2–5 years (energy intensive operations)

How to Reduce Biomass Boiler Cost

- Right–size the boiler — avoid oversizing which wastes capital and reduces efficiency.

- Secure local fuel suppliers to lower transport cost and price volatility.

- Invest in heat recovery (economizers, condensate return) to reduce fuel use.

- Choose proven manufacturers with good warranties and service networks.

- Plan for efficient storage & automatic feeding to lower ongoing labour costs.

Biomass Boiler Installation Guide (Step-by-Step)

Step 1 — Pre-installation assessment

- Heat load calculation (kW or ton/hr)

- Fuel availability & logistics study

- Site constraints, ventilation, and permitting checks

Step 2 — Installation

- Prepare foundation and civil works

- Deliver & place boiler (crane if required)

- Install fuel storage, conveyors, and feeding systems

- Fit flue/chimney and emission controls

- Connect water/steam piping and electrical controls

Step 3 — Testing & commissioning

- Pressure testing and safety checks

- Combustion tuning & emission testing

- Operator training and handing over documentation

Compliance: ensure local environmental and pressure-vessel regulations are followed and obtain all required permits.

Conclusion

In 2025, biomass boilers remain a compelling option for users with reliable access to biomass fuel and a long-term horizon for energy savings. Upfront costs are significant and vary widely by size and configuration, but careful design, local fuel sourcing and proper operation can deliver attractive payback periods — especially for industrial steam users.

If you’re considering a biomass project, start with a detailed heat-load study and speak to certified suppliers for itemised quotes and lifecycle cost modelling.

If you have any needs, please contact us in your convenience.

View Reviews of our Customer

"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"We have been using the Fangkuai thermal oil boiler for our chemical plant for years and it has never let us down. The boiler is very durable and can withstand harsh conditions. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. Fangkuai's thermal oil boilers are top-notch and I highly recommend them to anyone in need of reliable heating solutions."

Chang

China"Fangkuai's auxiliary equipment has made my boiler system even better. The quality of the equipment is exceptional and the prices are very reasonable. The equipment has helped improve the efficiency and performance of my boiler system, which has led to significant cost savings. I highly recommend Fangkuai's auxiliary equipment to anyone in need of high-quality boiler accessories."

Maryk

UK"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil