Introduction

In chemical manufacturing, industrial boiler is an indispensable energy conversion equipment in the field of chemical manufacturing. It provides heat energy for chemical production by heating water to a certain temperature or converting it into steam through the heat generated by fuel combustion. Its performance directly affects the production efficiency, quality and safety.

The Role of Steam in Chemical Manufacturing

Steam plays multiple key roles in chemical manufacturing. First, it is an efficient heat carrier that transfers heat quickly and evenly, and is used to heat raw materials, initiate chemical reactions, evaporate solvents, or dry products. For example, in petroleum refining, steam is used to heat crude oil for cracking reactions. Secondly, steam can also be used as a power source to drive steam turbines, steam pumps and other equipment to provide mechanical energy for production. In addition, in fine chemical industry, steam can be used to adjust the temperature and pressure of the reaction system, control the reaction rate and product distribution, and improve the product quality and yield.

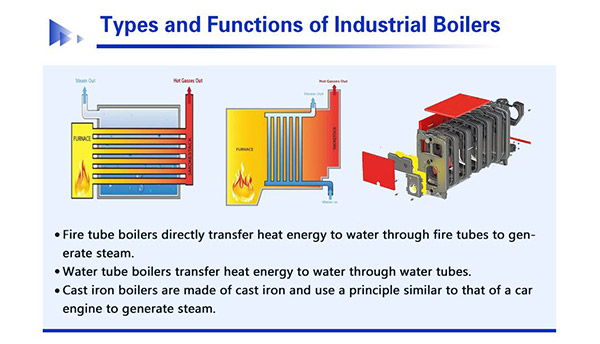

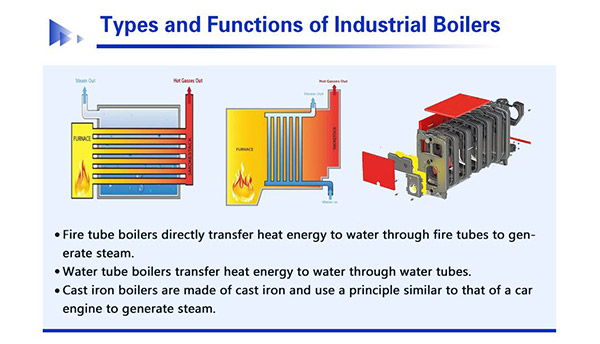

Types of Industrial Boilers Used in Chemical Plants

- Fired-tube boiler: The combustion chamber and flue gas passages of a fire-tube boiler are located in the lower part of the boiler, with water in the upper part.The high temperature flue gas vaporizes the surrounding water by heating it through a fire pipe. It has the advantages of simple structure, convenient operation, but it also has low thermal efficiency and the flue gas is easy to corrode the fire tube.

- Water-tube boiler: The water pipe boiler water flow in the pipe, high temperature flue gas flow outside the pipe, through the pipe Wall heat transfer. Ithas the advantages of high thermal efficiency, high evaporation intensity, and low water quality requirements, making it suitable for continuous production in large chemical plants. However, it has a complex structure, high installation and maintenance costs, and requires strict control of operating parameters.

- Waste heat boiler: The waste heat boiler produces steam by using waste heat resources such as high temperature waste gas and waste liquid in chemical production. It can improve energy efficiency, reduce production costs, reduce emissions, widely used in large-scale chemical enterprises. For example, it recovers waste heat fromcracking furnace and catalytic cracking units for use in other production units.

The key application of industrial boiler in chemical manufacture

Raw material preheating

Many chemical processes need to preheat raw materials in order to improve the reaction rate and conversion rate. Steam from industrial boilers passes heat through a heat exchanger to the raw material to reach the desired temperature.

Heating of chemical reactions

Many chemical reactions need to be carried out at high temperature. Steam or hot water provided by industrial boilers can provide heat for the reaction system. Such as sulfuric acid production, sulfur combustion heat is insufficient, the need for boiler steam heating reactor to ensure the smooth reaction.

Evaporation and crystallization are common separation and purification processes in chemical industry. The steam produced by the industrial boiler provides the heat source for the evaporator, vaporizes the solvent in the solution, obtain high-concentration solutions or crystals. For example, in the salt industry, steam is used to heat brine and evaporate water to obtain salt crystals.

The Industrial Boiler Has Obvious Advantages in the Chemical Industry

Stable heat source supply

Industrial boiler can provide heat energy according to the demand of chemical production. Whether continuous production or intermittent production, by adjusting the combustion intensity and water supply, to ensure a stable steam or hot water supply, ensure the continuity and stability of chemical production.

Efficient energy conversion

Modern industrial boiler adopts advanced combustion technology and heat exchange technology to convert fuel chemical energy into heat energy with high thermal efficiency. This can reduce energy consumption, reduce fuel costs and emissions, in line with the chemical industry energy-saving emission reduction requirements.

Adaptability to multiple fuels

Various fuels adaptive industrial boilers can choose coal, natural gas, fuel oil, biomass and other different fuels according to the local fuel resources. This fuel diversity provides more options for chemical companies to reduce the risk of fuel shortages or price fluctuations.

Challenges of Chemical Manufacturing Using Boilers

- Safety risks Industrial boilers are pressure vessels, There are safety risks in operation, such as explosion, leakage, etc. If the design, installation, operation and maintenance do not conform to the specifications, or operators lack professional knowledge and experience, easily lead to safety accidents, Caused casualties and property damage.

- The combustion of industrial boilers produces a large amount of waste gases, such as sulfur dioxide, nitrogen oxides and particulate matter. Direct discharge without treatment will seriously pollute the environment.

- Although modern industrial boilers have high thermal efficiency, some chemical enterprises have unreasonable operating parameters and aging equipment. There is still energy waste. Chemical enterprises should strengthen the monitoring and control of boiler operation, optimize the combustion process, adjust the water supply and air flow reasonably, maintain and reform the boiler regularly. Improve its performance and efficiency, and further improve energy efficiency.

Future Trends in the Application of Boilers in Chemical Plants

In the future, chemical plant boilers will develop in the direction of intelligence, clean energy, high efficiency, energy saving and comprehensive utilization of polygeneration. To meet the chemical industry for energy, environmental and economic benefits of the comprehensive requirements. Chemical enterprises should pay attention to the development of boiler technology, and actively adopt advanced technology and equipment to improve the operation level of boiler.

Conclusion

If you want to know more information about industrial boiler, welcome to contact us in yuor convenience.

View Reviews of our Customer

"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The hot water boiler from Fangkuai is amazing. It heats up quickly and efficiently, and the water stays hot for a long time. We have never had any issues with it and it has made a significant improvement in our daily operations. The installation process was also very smooth and the customer service was excellent. I highly recommend Fangkuai's hot water boilers."

Sarah

Canada"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"I am very impressed with the quality of Fangkuai's hot water boiler. It is built to last and has exceeded my expectations. The installation process was also very smooth and the customer service was excellent. The hot water boiler is very easy to operate and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's hot water boilers."

Jack

Australia"I am very impressed with the quality of Fangkuai's hot water boiler. It is built to last and has exceeded my expectations. The installation process was also very smooth and the customer service was excellent. The hot water boiler is very easy to operate and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's hot water boilers."

Jack

Australia"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico