Introduction

Industrial boilers are the backbone of modern industry. Whether generating electricity in a power plant or producing steam for manufacturing processes, boilers play a critical role in ensuring reliable energy supply and process efficiency. Choosing the right boiler and understanding its applications is essential for companies seeking to optimize operations, reduce costs, and meet environmental standards.

In this article, we’ll explore how industrial boilers work, their role in power generation and manufacturing industries, and what the future holds for boiler technology.

What Is an Industrial Boiler?

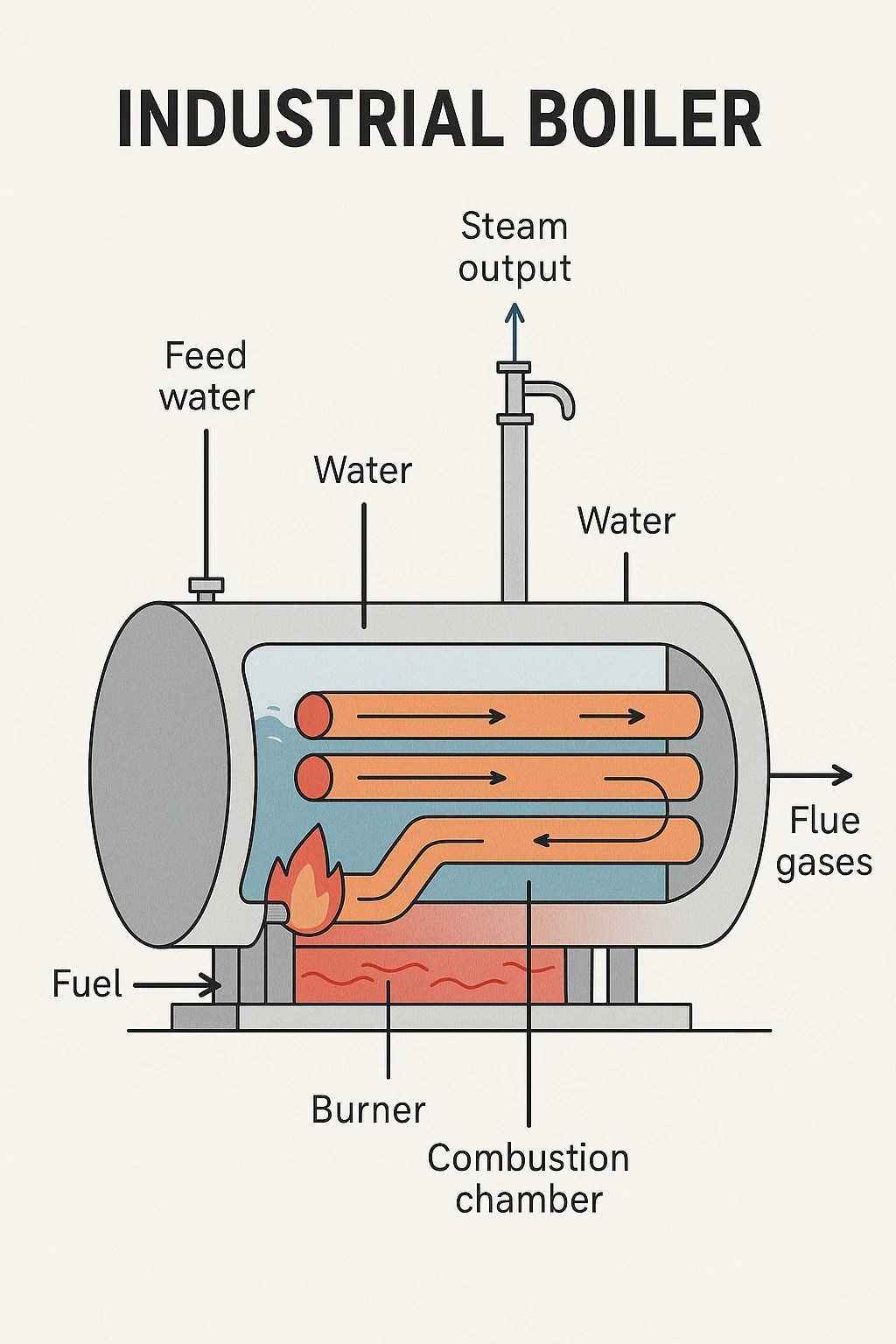

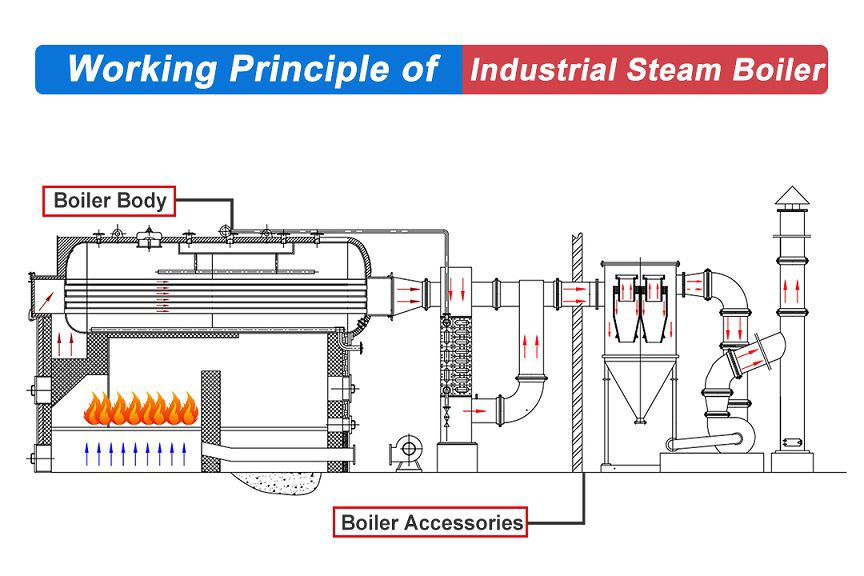

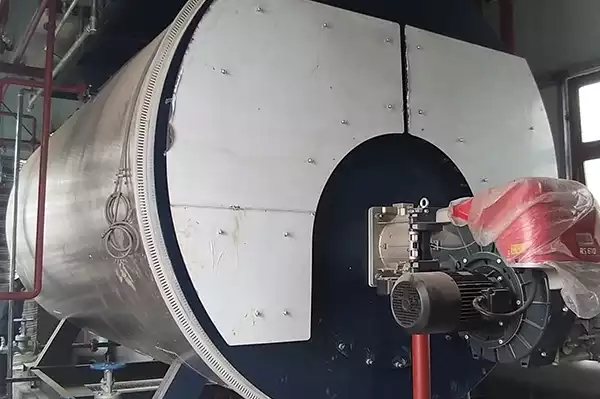

An industrial boiler is a large pressure vessel designed to convert water into steam or hot water using various fuels such as coal, natural gas, oil, or biomass. This steam or hot water is then used for heating, power generation, or direct industrial applications.

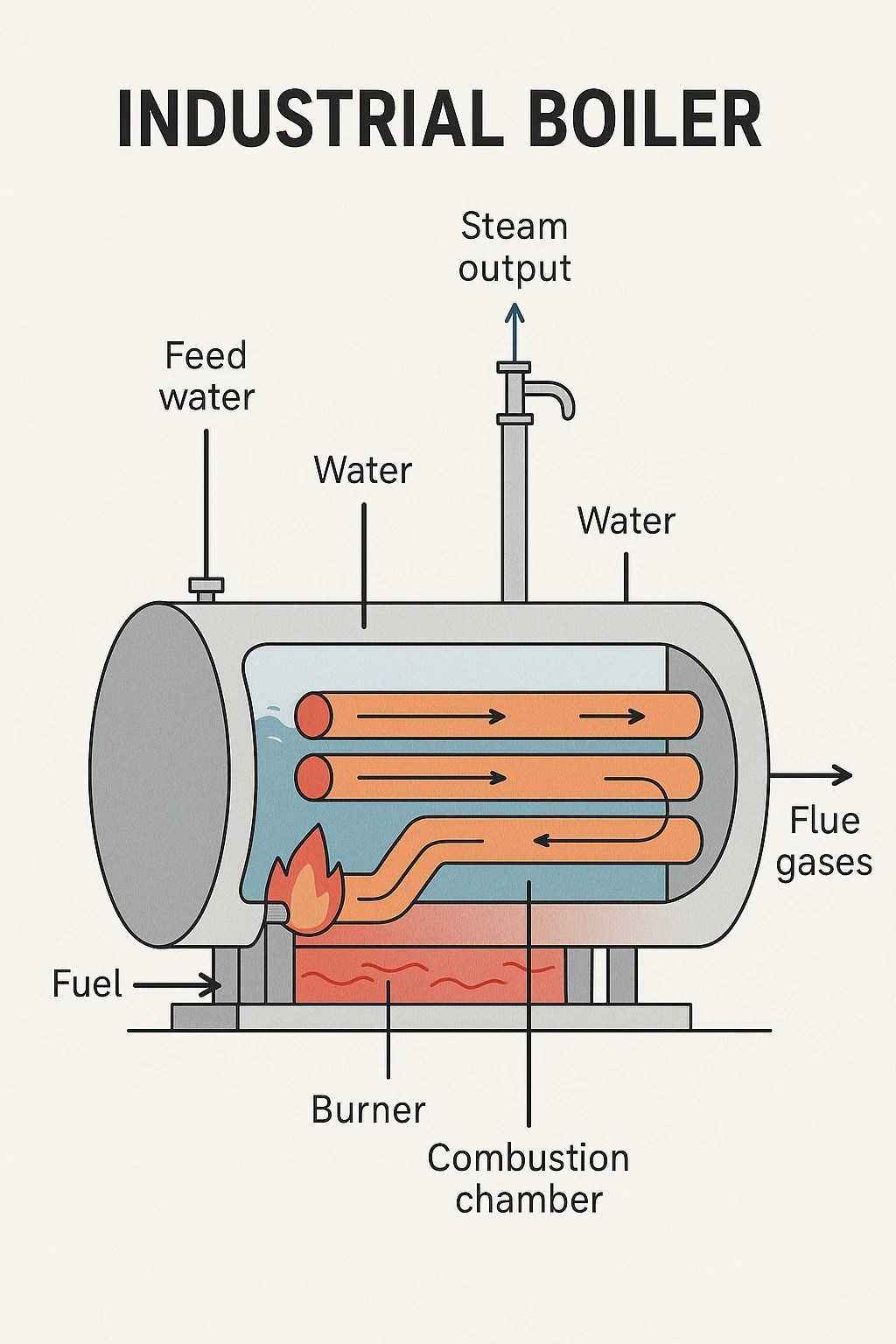

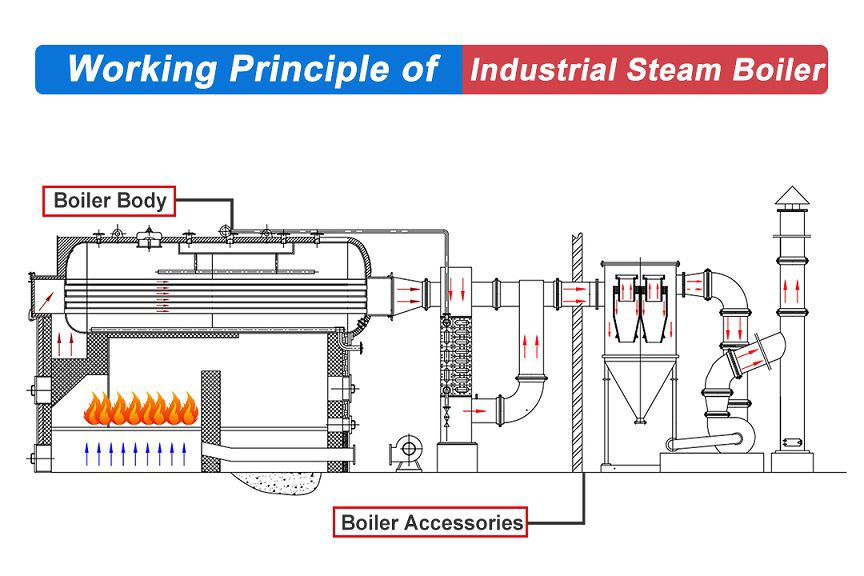

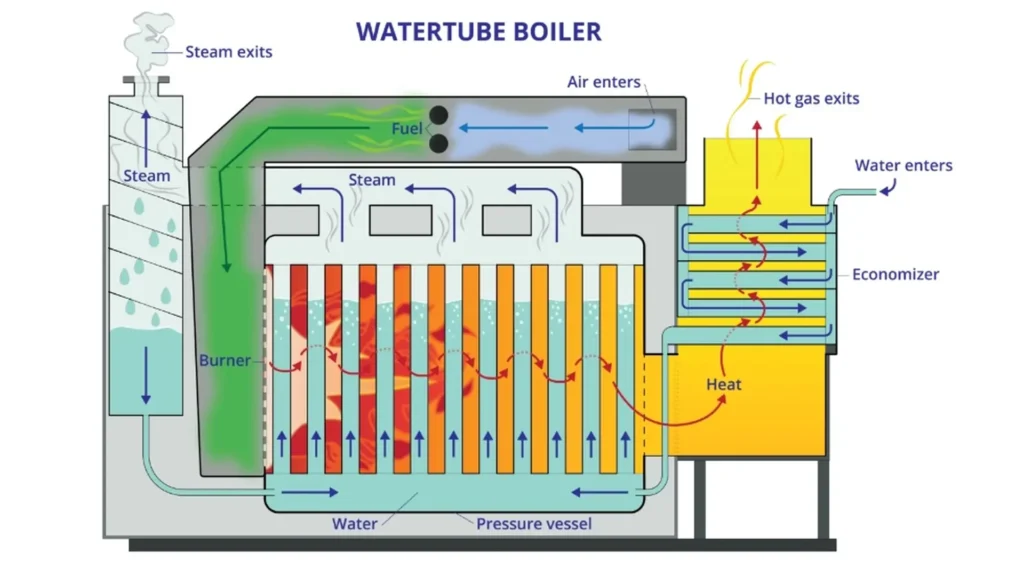

Key components of an industrial boiler include:

- Furnace: where fuel is burned to generate heat.

- Drum or Shell: stores water and steam.

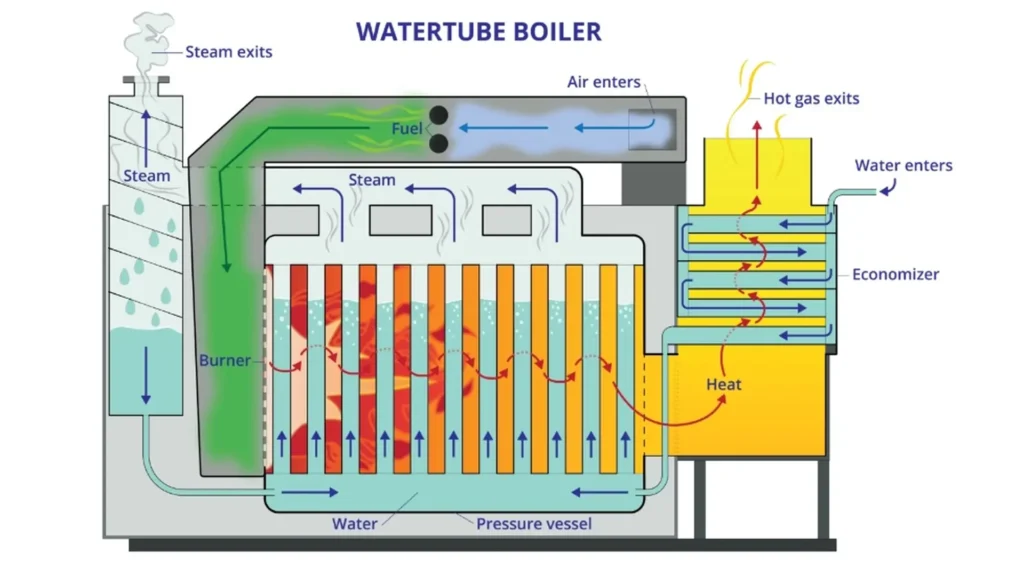

- Heat Exchangers (Superheaters, Economizers): improve efficiency by maximizing heat recovery.

- Controls and Safety Systems: regulate pressure, temperature, and flow to ensure safe operation.

Industrial boilers can be broadly categorized into:

- Fire Tube Boilers:hot gases pass through tubes surrounded by water; typically lower capacity.

- Water Tube Boilers: water flows inside tubes heated externally by combustion gases; suitable for high-pressure, high-capacity applications.

The Role of Industrial Boilers in Power Generation

Steam Production for Turbines

In power plants, industrial boilers generate high-pressure steam, which drives turbines to produce electricity. Without boilers, modern thermal power generation would not be possible.

Efficiency in Thermal Power Plants

The efficiency of power plants largely depends on the boiler’s ability to produce steam at optimal pressure and temperature. Advanced water tube boilers are designed to handle pressures above 100 bar and temperatures above 500°C, ensuring maximum turbine output.

Environmental Considerations

Power generation boilers are among the largest emitters of CO₂ and other pollutants. Regulations require plants to adopt technologies such as low-NOx burners, flue gas desulfurization (FGD), and electrostatic precipitators to reduce environmental impact.

Case Example

In a 500 MW coal-fired power plant, the boiler is responsible for over 70% of total plant efficiency. Upgrading to a modern supercritical boiler can increase efficiency by 5–8%, reducing fuel consumption and emissions significantly.

The Role of Industrial Boilers in Manufacturing Industries

Food and Beverage Industry

Steam is vital for sterilization, pasteurization, cooking, cleaning, and brewing. For example, in dairy processing, steam ensures milk safety by killing harmful bacteria while preserving quality.

Chemical and Petrochemical Industry

Boilers provide process steam for chemical reactions, distillation, and heating. Stability and precise temperature control are critical in chemical manufacturing, making reliable boilers indispensable.

Textile Industry

Textile factories use boilers to provide steam for dyeing, finishing, and drying fabrics. Consistent steam pressure ensures uniform colors and high-quality finishes.

Paper and Pulp Industry

Boilers generate the steam required to cook wood chips into pulp and later dry the paper sheets. This industry demands large-capacity boilers to sustain continuous production.

Metals and Manufacturing

Industrial boilers supply heat for metal forming, forging, cleaning, and surface treatment. In heavy manufacturing plants, steam systems support multiple production lines simultaneously.

Advantages of Using Industrial Boilers in Industry

- High Energy Efficiency: Continuous supply of high-temperature steam improves production output.

- Versatile Fuel Options: Can operate on coal, gas, oil, or renewable biomass.

- Scalability: Suitable for both small facilities and large power plants.

- Integration with Waste Heat Recovery: Enhances efficiency by reusing exhaust heat.

Challenges and Future Trends

Rising Fuel Costs and Efficiency Demands

Energy-intensive industries are under pressure to reduce operating costs. Modern boilers now integrate advanced combustion controls and economizers to improve efficiency.

Emission Regulations and Cleaner Technologies

Governments worldwide are imposing stricter emission limits. Many industries are adopting:

- Low-NOx burners to cut nitrogen oxide emissions.

- Carbon capture technologies to reduce greenhouse gases.

Shift Toward Renewable Energy and Biomass Boilers

With global focus on sustainability, biomass boilers are increasingly replacing coal-fired systems. Biomass uses organic waste such as wood chips and agricultural residues, providing a renewable and carbon-neutral solution.

Industrial Boiler Automation and Smart Control Systems

The future of industrial boilers lies in digitalization. IoT-enabled smart boilers allow real-time monitoring, predictive maintenance, and optimization of fuel usage, reducing downtime and maximizing efficiency.

Conclusion

Industrial boilers are indispensable in both power generation and manufacturing industries. They provide the steam and heat required to drive turbines, sterilize food, produce chemicals, dye fabrics, and much more.

As industries face increasing pressure to cut costs and reduce emissions, modern boiler technologies are evolving toward higher efficiency, lower environmental impact, and smarter automation systems.

For more insights, please contact us at +0086 132 1322 2805 and we will provide you with a professional product quotation!

View Reviews of our Customer

"Fangkuai's steam generators are excellent. They are very easy to use and require minimal maintenance. The customer service at Fangkuai is also exceptional. They are very responsive and always willing to help. The energy efficiency of the steam generators is also remarkable, which has helped me save money on my energy bills. I highly recommend Fangkuai's steam generators."

Maria

Spain"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"The steam generator from Fangkuai is perfect for my small business. It is very easy to use and requires minimal maintenance. It is also very energy efficient, which has helped me save money on my energy bills. The customer service at Fangkuai is also excellent. They are very responsive and always willing to help. I highly recommend Fangkuai's steam generators."

Ahmed

Egypt"The thermal oil boiler from Fangkuai is very easy to operate and maintain. It has helped us save time and money on maintenance, which has led to significant cost savings. The quality of the materials and the construction of the boiler are exceptional. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's thermal oil boiler ."

Allen

Brazil"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"The steam boiler from Fangkuai is perfect for my food processing business. It meets all of our requirements and is very reliable. The quality of the materials and the construction of the boiler are exceptional. It is also very easy to operate and maintain, which has helped us save time and money on maintenance. I highly recommend Fangkuai's steam boilers to anyone in need of reliable heating solutions."

Json

Brazil"I purchased a Fangkuai steam boiler for my factory and it has been working flawlessly for months now. The quality of the materials and the construction of the boiler are impressive. It is also very energy efficient, which has helped us save money on our energy bills. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

John

USA"The customer service at Fangkuai is top-notch. They helped me choose the perfect boiler for my needs and provided great support throughout the process. The installation process was also very smooth and the boiler has exceeded my expectations. It is very easy to use and maintain, and the energy efficiency is remarkable. I highly recommend Fangkuai's products to anyone in need of reliable and efficient heating solutions."

Juan

Mexico