Biomass fuel is becoming an increasingly popular source of renewable energy because it is environmentally friendly and has a low carbon footprint. Biomass fuel feeding systems are used to transfer biomass fuels from the storage silos to the boilers for combustion. 在这个博客中, we will be discussing the main components of a biomass fuel feeding system and how they work.

A biomass boiler system, in technical terms, is a heating system that utilizes biomass as a renewable energy source to generate heat. Biomass refers to organic materials, 例如木颗粒, 农业废弃物, 或专用能源作物, which are used as fuel in the boiler system.

FANGKUAI, as a global leader in boiler technology, has made significant strides in developing innovative biomass boiler systems that are highly efficient and environmentally friendly. Our biomass boilers are equipped with advanced combustion technology to ensure optimal conversion of biomass into heat energy, minimizing harmful emissions and maximizing energy efficiency.

Companies use fuel storage silos to store bulk biomass fuel supplies. These silos come in various sizes, constructed from concrete, steel, or aluminum, tailored to specific requirements. Depending on the application, the silos can be situated either indoors or outdoors.

Fuel feed augers play a crucial role in transporting biomass fuel from storage silos to the boiler grate for combustion. Augers utilize a screw mechanism that propels the fuel through a tube or channel towards the boiler.

The fuel distributor ensures an even distribution of fuel across the boiler grate. This can involve a rotating arm moving across the grate for uniform fuel distribution, or a stationary distribution system can be employed.

Energy production begins on the fuel grate, where biomass fuel undergoes combustion. The design of the grate varies based on the specific fuel type being burned.

The biomass fuel feeding system is effectively operated and monitored through a control system. This system can incorporate automatic controls that regulate the fuel flow rate in response to the boiler’s load.

Biomass fuel feeding systems offer several advantages over traditional fossil fuel systems:

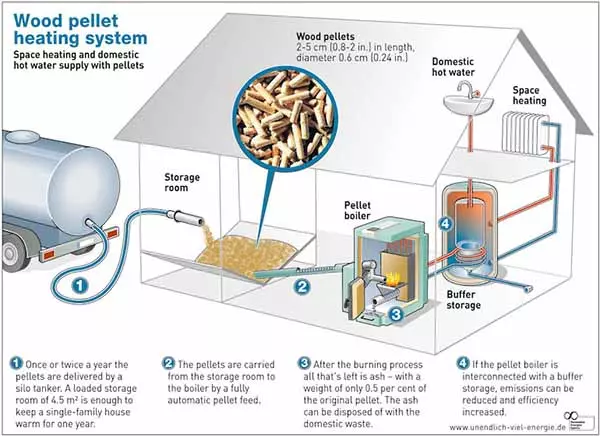

To provide fuel for a biomass boiler, several methods can be utilized. One common approach is through the use of a fuel storage and handling system. This system typically includes components such as fuel storage silos or containers, conveyors or augers for transporting the fuel, and equipment for unloading and feeding the fuel into the boiler.

The specific design and configuration of the fuel storage and handling system may vary depending on the type and characteristics of the biomass fuel being used. 例如, wood pellets may require a different handling system compared to agricultural waste or dedicated energy crops.

Grate boilers find widespread application in biomass combustion and exhibit the capacity to accommodate an array of fuel types, encompassing wood fuels, 煤炭, waste fuels, peat, and even straw. Within these boilers, a grate mechanism takes center stage, facilitating the fuel’s introduction onto the grate. This movement can be governed through adjustable gates or the manipulation of the fuel movement speed positioned below the gate. As the fuel traverses the grate, combustion occurs, engendering heat that powers the boiler.

The biomass boiler process consists of a series of distinct stages. To begin with, biomass fuel, encompassing materials such as wood pellets or agricultural waste, is initially stored in a dedicated fuel storage silo or container. Following this, the fuel is efficiently conveyed to the boiler using conveyors or augers, streamlining the process and ensuring a consistent fuel supply.

Inside the boiler, the biomass fuel undergoes combustion, thereby releasing heat energy. This heat is then harnessed to convert water into steam through a steam-water system. The process begins with water heating, followed by evaporation, and ultimately superheating, all powered by the energy derived from combustion. Essential components encompass tubes, pipes, 阀门, and diverse fittings.

The steam generated serves a multitude of purposes, including building heating, 水加热, or even electricity generation by means of steam turbines. 此外, specific biomass boilers can employ thermochemical techniques to manufacture liquid or gaseous fuels such as renewable diesel, methane, or even renewable jet fuel.

现在, let’s embark on the journey of designing a biomass fuel feeding system that seamlessly integrates with your boiler setup. The cornerstone of this process is determining your fuel storage requirements and capacity. Accurate calculations prevent interruptions in fuel supply and guarantee your system’s reliability.

Fuel handling equipment plays a pivotal role in this system. From screw conveyors that ensure a consistent feed rate to hoppers equipped with agitators that prevent bridging, your choice impacts the overall efficiency. Tailor your selection to suit your needs, whether it’s precise delivery or preventing fuel clogs.

At the core of the system rests the fuel delivery mechanism, a pivotal element in sustaining continuous boiler operation. Consider it akin to a symphony – the delivery system’s precision orchestrates each note in perfect harmony, ensuring a seamless performance.

With the design in place, it’s time to bring your biomass fuel feeding system to life. Proper site preparation is paramount, shielding your equipment from the elements and ensuring safety for both operators and equipment. Mother Nature can be unpredictable, but a well-prepared site can weather any storm.

The installation process involves configuring fuel storage and handling equipment. This step requires attention to detail – every connection, every setting matters. The components must work in tandem, like pieces of a puzzle coming together to form the big picture.

Connecting the fuel delivery system to the boiler is the moment of truth. Compatibility is key here, ensuring that the feed system seamlessly integrates with the boiler. As you make these connections, envision the energy flow – a continuous dance between the fuel and the boiler, choreographed for optimum efficiency.

Biomass fuel feeding systems are an important part of any biomass boiler system. They allow for the efficient and reliable transfer of biomass fuels from storage to the boiler for combustion. The advantages of biomass fuel systems make them an attractive alternative to traditional fossil fuel systems. With the increasing demand for renewable energy sources, biomass fuel systems will continue to grow in popularity and become a more common sight in industrial, 商业的, and residential settings.

免费锅炉报价

没有延迟, 得到 3 今日报价 比较最优惠的价格 安全可靠评论

本文内容?

V查看我们客户的评论

"方快的热水器太棒了. 升温快速高效, 而且水会长时间保持高温. 我们从来没有遇到过任何问题,它在我们的日常运营中取得了显着改善. 安装过程也很顺利,客服态度也很好. 强烈推荐方快的热水器。"

莎拉

加拿大"方快的蒸汽发生器很优秀. 它们非常易于使用并且需要最少的维护. 方快的客户服务也很出色. 他们反应灵敏,乐于助人. 蒸汽发生器的能源效率也非常出色, 这帮助我节省了能源费用. 强烈推荐方快的蒸汽发生器。"

玛丽亚

西班牙"方快的蒸汽锅炉非常适合我的食品加工业务. 它满足我们的所有要求并且非常可靠. 材料的质量和锅炉的构造非常出色. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 我向任何需要可靠供暖解决方案的人强烈推荐方快的蒸汽锅炉。"

杰森

巴西"我们化工厂一直在使用方快导热油锅炉多年,从未让我们失望过. 锅炉非常耐用,可以承受恶劣的条件. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 方快的导热油锅炉是一流的,我强烈推荐给任何需要可靠供暖解决方案的人。"

张

中国"方快的辅助设备让我的锅炉系统更上一层楼. 设备质量卓越,价格非常合理. 该设备帮助提高了我的锅炉系统的效率和性能, 这导致显着的成本节约. 我向任何需要优质锅炉配件的人强烈推荐方快的辅助设备。"

马里克

英国"方快的热水器太棒了. 升温快速高效, 而且水会长时间保持高温. 我们从来没有遇到过任何问题,它在我们的日常运营中取得了显着改善. 安装过程也很顺利,客服态度也很好. 强烈推荐方快的热水器。"

莎拉

加拿大"我为我的工厂购买了一台方快蒸汽锅炉,它已经完美运行了几个月了. 材料的质量和锅炉的结构令人印象深刻. 它也非常节能, 这帮助我们节省了能源费用. 我向任何需要可靠高效供暖解决方案的人强烈推荐方快的产品。"

约翰

美国"方快的蒸汽锅炉非常适合我的食品加工业务. 它满足我们的所有要求并且非常可靠. 材料的质量和锅炉的构造非常出色. 它也非常容易操作和维护, 这帮助我们节省了维护时间和金钱. 我向任何需要可靠供暖解决方案的人强烈推荐方快的蒸汽锅炉。"

杰森

巴西"方快的客户服务是一流的. 他们帮助我选择了满足我需求的完美锅炉,并在整个过程中提供了大力支持. 安装过程也很顺利,锅炉超出了我的预期. 非常易于使用和维护, 能源效率显着. 我向任何需要可靠高效供暖解决方案的人强烈推荐方快的产品。"

娟

墨西哥